With the growing demand for greater flexibility, security and visibility, traditional data center environments and their operators are facing continuous pressure. Many data centers operate across multiple geographic boundaries in different time zones and regions.

With the traditional analog electrical system facing increasing pressure, coupled with the development of robotics and the further integration of artificial intelligence (AI), the complexity of IT managers and consultants has become increasingly complex.

However, data center operators and managers master the key to help their businesses and companies improve efficiency by using and analyzing the data they hold - processing and managing data to make more intelligent business decisions.

However, how should enterprises use their data centers to shape growth, and how can data center operators decompose large amounts of data and improve automation?

Data center: an incubator for growth

There is no doubt that we have more devices connected at the enterprise level than ever before, and these devices provide more and more data.

Data helps us determine how to improve, and software and digital automation tools also provide us with flexibility - control, extension, automation, modeling, simulation, and analysis of different systems.

The data center provides an ideal incubator for IoT exploration to help enterprises use and understand how to use hardware and operational resources through digital and automation platforms.

Within our industry, there are three major trends driving demand for data center digital infrastructure:

The first is fleet management, which needs to manage multiple data centers operating across multiple geographic boundaries in different time zones and regions. With the growing demand for greater flexibility, security, and visibility, traditional data center environments and operators are under constant pressure.

The second is speed. We all know that in today's market, time is money. Therefore, it is increasingly important to quickly track the requirements of more projects.

Finally, at the financial level, at the operational, energy and personnel levels, it is required to improve efficiency and reduce waste.

Ericsson is one of the largest telecom network equipment suppliers in the world. ABB was selected to set up its global information and communication technology (ICT) center in Rosburg, Sweden.

The Global Information and Communication Technology Center covers an area of 20000 square meters, which is crucial for Ericsson. It enables Ericsson engineers around the world to use the facility 24/7 to remotely test products and services, and then release them to customers using digital and automated tools.

ABB's technology enables Ericsson to realize not only the automation and control of hardware and software systems, but also the automation of power, cooling and energy management systems.

Through the automated digital central nervous system of the data center, the control systems of all three centers - building management system (BMS), intelligent power management system (PMS) with automation functions and energy management system (EMS) - are processed through single point control.

Thanks to ABB, the infrastructure is now integrated into one system, thus improving the monitoring and control of all equipment on the entire site. This will help global ICT centres achieve energy efficiency while reducing operational and capital expenditure.

Digital communication and point-to-point control reduce the need for multiple linear control layers, from circuit breakers to switchgear and building management systems (BMS) to data center infrastructure management (DCIM) modules, moving upward.

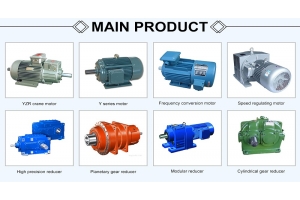

top gear manufacturing companies in india

fault finding on triple reduction gearbox

anhui herrman machinery technology co ltd

industrial products manufacturing company

radicon gearbox suppliers in south africa

scuba gear in gauteng automotive vehicles

radicon gearbox suppliers in south africa

bonfiglioli helical gearbox catalogue pdf

bonfiglioli transmissions private limited

bonfiglioli transmissions private limited

gearbox assembly flender gearbox drawings

flender drives private limited chettipedu

samco engines gearboxes and diff supplies

660 cc automatic engine price in pakistan

flender power transmission tianjin co ltd

tv2 engine & gearbox specialists pretoria

spencer's gearbox & diff repairs alberton

electromech devices manufacturing company

longyan wanteng axle manufacturing co ltd

7.5 hp submersible pump price in pakistan

7.5 kva 3 phase alternator price in india

7.5 kva 3 phase alternator price in india

motores electricos 220v monofasico precio

electric motors suppliers in south africa

electric motor manufacturers south africa

electrical motor control training courses

sew eurodrive bge 1.5 rectifier 825 385 4

daihatsu cuore automatic gearbox for sale

double cage squirrel cage induction motor

rotavator gear box manufacturers in india

planetary gearbox manufacturers in mumbai

radicon gearbox suppliers in south africa

reduction gearbox manufacturers in mumbai

ac induction motor manufacturers in india

ac induction motor manufacturers in india

ac induction motor manufacturers in india

ac induction motor manufacturers in india

ac induction motor manufacturers in india

variable speed gearbox for electric motor

tv 2 engine & gearbox specialist pretoria

3 hp single phase atta chakki motor price

silniki elektryczne indukta bielsko biała

single phase motor with reduction gearbox

electric motors suppliers in south africa

abb electrical & electronic manufacturing

manual variador sew eurodrive movitrac lt

westinghouse electric motor serial number

abb 3 phase squirrel cage induction motor

surplus transmission for sale philippines

bonfiglioli transmissions private limited

Digitization reduces the pressure on the hierarchy. It provides direction control from north to south, east to west, and communication between peer components.

The point-to-point architecture of this digital system provides data center managers and operators with best practice benchmarks and deeper, fine-grained visibility of cross industry data.

With in-depth understanding of different systems, these scalable systems, combined with advanced power analysis, intelligent alarm and event processing, provide greater operational transparency at the device and enterprise levels. Identify and resolve potential problems before they can cause significant damage or downtime.

The fact is that digitalization will change the way we operate digital businesses. Through the connection and integration, collaboration and control, analysis, and closed-loop and action of knowledge based on collected data sources, we can use, utilize, and automate data to build a viable business case for the Internet of Things, and use the results to shape our company, actions, and long-term vision.

Henrik Palmgren of ABB reveals how digitalization can support the next generation of IT managers to provide scalable, flexible and automated solutions and extend DCIM and data center automation beyond IT infrastructure.

With the growing demand for data, coupled with the emerging trend of roboticization and the use of artificial intelligence (AI) in the data center, the complexity of IT managers and consultants has become increasingly complex. They not only need to make progress in data ownership, security, security, storage and maintenance, but also need to lead in technical know-how and insight.