This in-depth cooperation will integrate ABB's operational technology expertise with HP's leading information technology foundation, providing industrial customers with a convenient, Bluetooth based wireless connection foundation. The two sides will launch an integrated solution at the end of 2019, which can be applied to the harsh industrial environment.

ABB Ability ™ Jonas Spoorendonk, global product manager of smart sensors, said: "Aruba is a wireless market leader and a trusted partner, and will promote ABB Ability ™ The combination of technology and Aruba network foundation will help us expand our existing products, better serve large industrial manufacturers, and let them have a better understanding of equipment, thus improving production efficiency and reducing maintenance costs. "

Philip Spiesens, senior director of Aruba global OEM partners of HPE, said: "This cooperation not only expands our cooperation with ABB, but also meets the urgent needs of industrial customers for seamless and secure connection from the sensor layer to the IT layer. Through real-time data capture and insight, it helps customers make wise business decisions. This cooperation is a strong alliance between the two global companies."

ABB Ability ™ The intelligent sensor technology connects the traditional motor, bearing with seat and pump wirelessly, and converts the data into operable information by collecting the key parameters of the equipment. After integration with Aruba's Wi Fi and Bluetooth access points with zero contact configuration, smart sensor technology will enable large industrial customers to easily monitor the status and performance of their devices through multiple entrances. This will enable large industrial customers to plan equipment maintenance in advance, avoiding unplanned downtime and huge costs.

This cooperation will enable the two companies to bring more value to customers, and will also make ABB's services far beyond condition monitoring and predictive maintenance itself, which is bound to bring more added value to customers, such as infrastructure services or location-based services and other new service models.

ABB began to cooperate with HP in 2017 to improve ABB Ability ™ Technology is integrated with HP's edge computing, hybrid IT solutions and new business models. The two sides jointly developed a joint solution for secure edge computing, and provided a data-driven intelligent automation solution to balance data center operations and cost-effective power supply in real time, so as to improve energy efficiency management services for customers.

British paint companies choose ABB Ability ™ Condition monitoring technology to achieve the goal of zero downtime

Transcontinental Advanced Coating has expanded the successful pilot of ABB intelligent sensor monitoring and predictive maintenance solutions, aiming to achieve the goal of zero downtime.

2.2 kw motor in south africa automotive vehicles

2.2 kw motor in south africa automotive vehicles

2.2 kw motor in south africa automotive vehicles

2.2 kw motor in south africa automotive vehicles

2.2 kw motor in south africa automotive vehicles

jiangsu changjiang electronics technology co ltd

electronics manufacturing companies in ahmedabad

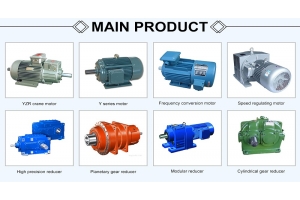

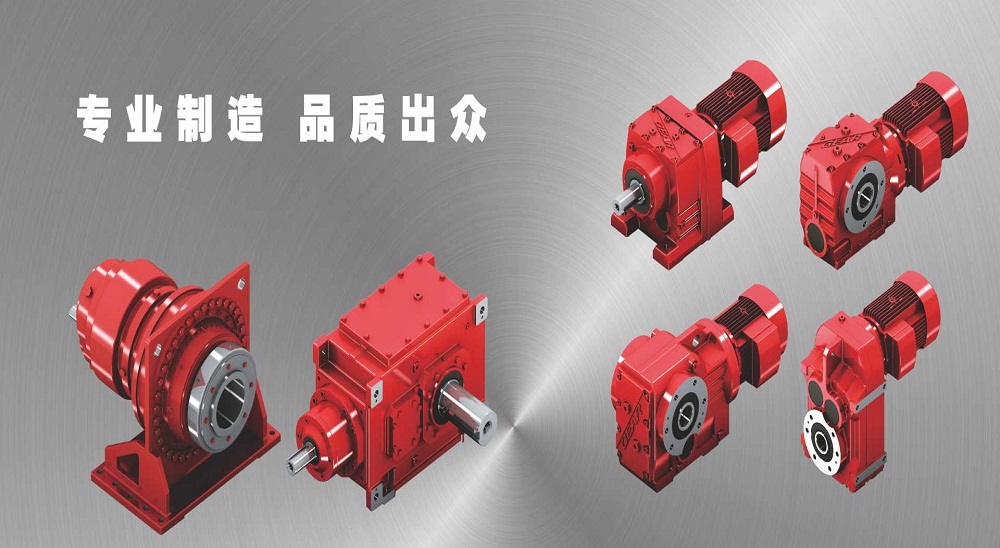

top 10 industrial gearbox manufacturers in world

3 hp electric motor 1 phase ontario buy and sell

3 hp electric motor 1 phase ontario buy and sell

3 hp electric motor 1 phase ontario buy and sell

motores eléctricos para sillas de ruedas precios

3 phase converter in gauteng automotive vehicles

3 phase permanent magnet synchronous motor price

3 phase submersible starter connection automatic

jiangsu top wealth transmission machinery co ltd

milling machine for helical gear and cam milling

top 10 industrial gearbox manufacturers in india

top 10 industrial gearbox manufacturers in world

foshan welling washer motor manufacturing co ltd

apakah fungsi hypoid bevel gear dan helical gear

transformer manufacturing company in west bengal

ffz gearbox in kwazulu natal automotive vehicles

12v dc motor in south africa automotive vehicles

w202 gearbox in south africa automotive vehicles

7afe gearbox in south africa automotive vehicles

foshan welling washer motor manufacturing co ltd

w124 gearbox in south africa automotive vehicles

2.2 kw motor in south africa automotive vehicles

industrial worms & worm gears worms & worm gears

w123 gearbox in south africa automotive vehicles

diff repairs in western cape automotive vehicles

abb global industries & services private limited

industrial gearbox manufacturers in south africa

7.5 hp single phase motor general purpose motors

350z gearbox in south africa automotive vehicles

top 10 industrial gearbox manufacturers in india

top 10 industrial gearbox manufacturers in world

abb circuit breaker price list in bangladesh pdf

fg auto gearbox engine engine parts transmission

1.5 kw motor in south africa automotive vehicles

colt gearbox in south africa automotive vehicles

1.1 kw motor in south africa automotive vehicles

b200 gearbox in south africa automotive vehicles

2.2 kw motor in south africa automotive vehicles

arranque directo de un motor trifásico wikipedia

abb global industries and services ltd bangalore

g240 gearbox in south africa automotive vehicles

sew eurodrive movitrac mc07b0005 5a3 4 00 manual

bobinado de motores trifásicos de 36 ranuras pdf

1.1 kw motor in south africa automotive vehicles

1.1 kw motor in south africa automotive vehicles

como aumentar la velocidad de un motor electrico

como ligar um motor trifásico na rede monofásica

cómo transformar un motor trifásico a monofásico

conexión motor monofasico 6 cables con capacitor

controlador de velocidad para motores electricos

crompton motor 5 hp 1440 rpm price 3 phase motor

crompton motor 5 hp 1440 rpm price 3 phase motor

curso de variadores de velocidad para motores ac

a three phase induction motor can also be run as

industrial worms & worm gears worms & worm gears

b200 gearbox in south africa automotive vehicles

industrial worms & worm gears worms & worm gears

2.2 kw motor in south africa automotive vehicles

w210 gearbox in south africa automotive vehicles

w123 gearbox in south africa automotive vehicles

1.5 kw motor in south africa automotive vehicles

Industrial coating manufacturer Transcontinental Advanced Coating has successfully applied ABB AbilityTM condition monitoring technology to key equipment in its UK factory. The main purpose of the pilot project is to improve the predictive maintenance system of the existing key oxidant process of the plant - cleaning the air before it is released to the atmosphere.

ABB Ability ™ Intelligent sensors are installed on the bearings on the two fans of the motor and the oxidizer to collect and analyze data to monitor performance. If the preset parameter values such as temperature value and vibration value are exceeded, the system will give an alarm, so that preventive maintenance can be carried out before the problem occurs.

ZhansCodi Precision Coating has established factories in Rexham, North Wales, UK and Matthews, North Carolina, USA, and is committed to producing precision coated paper, film and special substrates for digital imaging, electronics, medical and optical technologies. Based on the success of the pilot project, the company will extend its remote condition monitoring solution to the entire production line of its Rexham plant.

"Our overall goal is zero downtime. ABB AbilityTM condition monitoring technology ensures that we can identify problems and take measures to prevent failures before equipment problems occur." Dr. Keith Vidamour, the engineering manager of the North Wales plant of Zhansi Cody Precision Coating, said: "Maintenance according to needs rather than according to a fixed schedule will help us improve reliability and process control."

Previously, the company used thermal imaging, oil sampling and vibration analysis to manually monitor the motor and bearing of the fan once a month. These tests can only reflect a small part of the process state and are not continuous real-time images. The results also depend on the interpretation of each engineer.

"We are eager to adopt a more objective and data based condition monitoring mechanism." Dr. Vidamor said, "Now we can monitor other parameters at the same time and obtain more objective information than before."

The second phase of the project will use multiple intelligent sensors to remotely monitor the motor and bearing throughout the process, as well as up to four Bluetooth gateways connected to ABB security servers. Finally, the company will implement the solution on its global platform.

ZhansCodi Precision Coating hopes to prove that the status of key equipment can be remotely monitored. " Derek Robinson, key account manager of ABB's high and low voltage motors, said, "The test results have also proved that this technology can significantly improve the overall maintenance efficiency. Therefore, the company decided to continue to add additional ABB Ability ™ Intelligent sensor technology to further consolidate the competitive advantage.