ABB Flameproof motor Ex d M3JP 315 SMC 8 90kW IE3 3GJP314230-CDG

Low voltage Motors for explosive gas atmospheres, Flameproof motors Ex db IIB/IIC T4 Gb

The following combinations are possible: – Ex db IIB/C T4 Gb / Ex tb IIIB/C T125°C Db – Ex db eb IIB/C T4 Gb / Ex tb IIIB/C T125°C Db – Ex eb IIC T3 Gb / Ex tb IIIB/C T125°C Db – Ex ec IIC T3 Gc / Ex tc IIIB/C T125°C Dc

– Single speed electric motors (single and three- phase), 50 and 60 Hz – 2, 4, 6 and 8 poles – Rated output P N from 0.12 kW to 1000 kW – Rated voltage U N above 50 V up to 1 kV – Motors, capable of continuous operation at their rated power with a temperature rise within the specified insulation temperature class – Motors, marked with any ambient temperature within the range of -20 °C to +60 °C – Motors, marked with an altitude up to 4000 m above sea level

The marking of the products certified according a specific local certification system is usually differing from the ATEX and IECEx markings, this means that the ATEX and IECEx markings will be replaced with the markings required for the local certification system if a such is ordered. IEC/EN 60034-30-1: 2014 This standard defines four International Efficiency (IE) classes for single-speed electric motors that are rated according to IEC 60034-1 or IEC 60079-0 (explosive atmospheres) and designed for operation on sinusoidal voltage. ABB offers motors for explosive atmospheres for use with variable speed drives with the following protection types: flameproof, increased safety (on request), non-sparking, and dust ignition proof.

– IE4 = Super premium efficiency – IE3 = Premium efficiency, identical to the table in 10CFR431 (‘NEMA Premium’) in the USA and CSA C390-10:2015 for 60 Hz – IE2 = High efficiency – IE1 = Standard efficiency

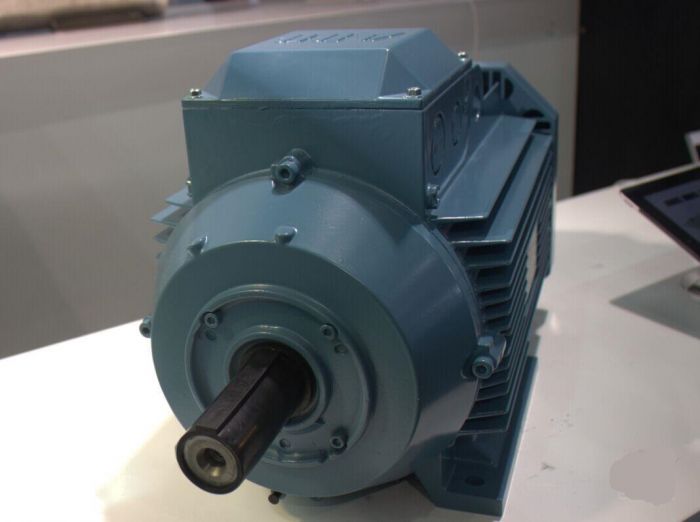

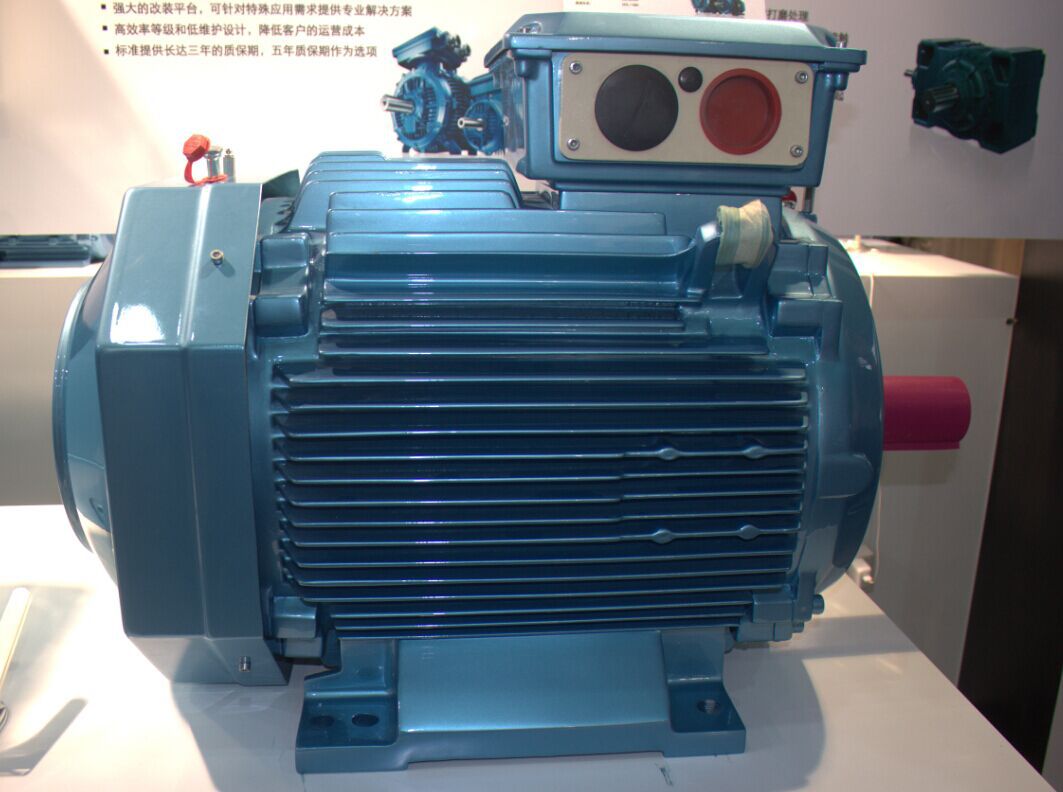

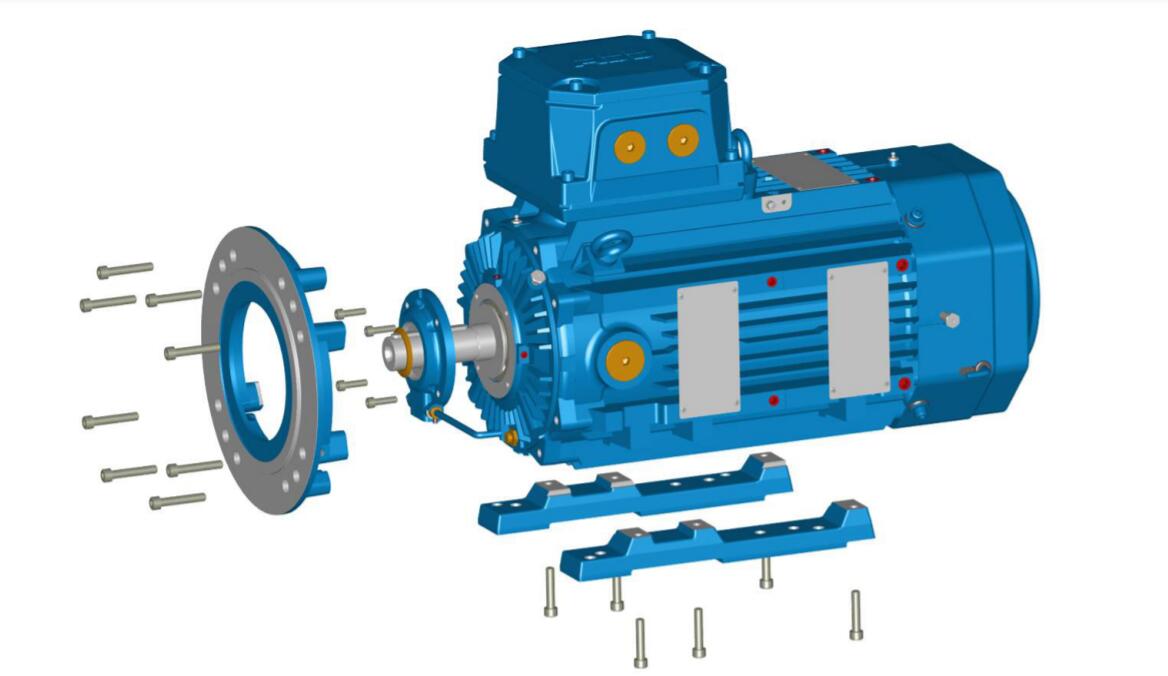

A: Foot-mounted, top-mounted terminal box B: Flange-mounted, large flange with clearance holes C: Flange-mounted, small flange with tapped holes

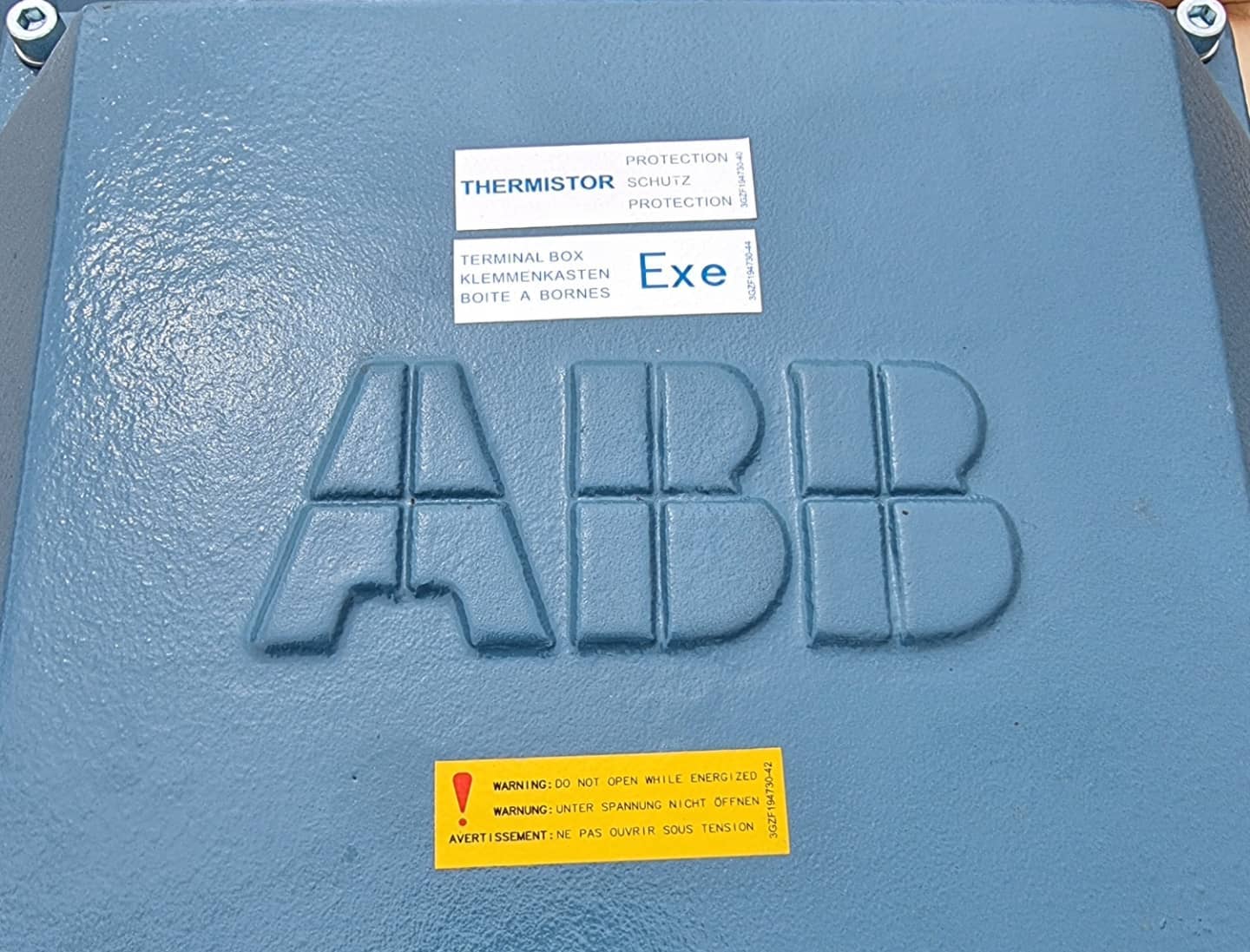

The motor enclosure is designed in such a way that no internal explosion can be transmitted to the explosive atmosphere surrounding the motor. The enclosure must withstand, without damage, any pressure levels caused by an internal explosion. The shape, length and gap of joints of part assemblies, at shaft openings, cable entries, etc., shall be designed to allow for throttling and cooling of hot gases escaping outside.

The standards emphasize the impact of an explosive atmosphere (for instance, explosion pressure) over constructional requirements of such apparatus. Work on accessories of enclosure components is only permitted using prescribed tools. Cable entries must meet the requirements of this type of protection. The temperature of the motor’s external enclosure shall not exceed the self-ignition temperature of the explosive atmosphere of the installation area during operation. For this reason, rated output depends on this rated maximum temperature for the area in question.

The standard temperature class on flameproof motors from ABB is T4 (135 °C), other temperature classes as T5 (100 °C) and T6 (85 °C) are available on request. No motor device outside the flameproof enclosure (e.g., ventilator) shall be a potential source of sparks, arcs or dangerous overheating. Motors for explosive atmospheres have to be officially approved by a recognized test organization, authorized to issue test certificates, to ensure compliance with standards for this type of equipment. ABB low voltage motors for explosive atmospheres are classified according to the categories, protection types and equipment protection type which are specified in the relevant standards. Depending on the nature of the potentially explosive atmosphere, it is the responsibility of the user to determine which group and which maximum surface temperature should be specified for the motor installation. The motors are rated and certified for ambient temperature between –20 °C and +40 °C according to standards. For ambient temperatures below –20 °C and above +40 °C certificates are available for most of the motors.

ABB’s motors conform to the stringent standards set by CENELEC (European Committee for Electro- technical Standardization) and IEC (International Electrotechnical Commission), and are approved by testing laboratories and certification bodies (ExCB). The motors can be certified according to the ATEX Directive by any of the Notified Bodies “ExNB” of EU member countries. These motors are therefore acceptable in all EU countries and many other countries. In addition, IECEx certificates are avail- able for the most motor types. These certificates can be issued by any registered IECEx certification body (ExCB) worldwide. ABB is maintaining a wide selection of local certificates for the different products, please refer to the variant code section for each product for information about availability.

| Type | M3JP |

|---|---|

| Voltage Class | Low Voltage < 690V |

| Feature | Flameproof & Explosion Proof motor |

| Motor Rotor Type | 3-Phase squirrel cage motor |

| Enclosure | Totally Enclosed Fan Cooled (TEFC) |

| IE Class | IE3 |

| Motor Power (KW) | 90 KW |

| Number of Poles | 8 |

| IP Rating | IP55 |

| Mounting Position | IM B14 |

| Frame Type | IEC |

| Frame Size | 315SMC |

| Housing Material | Cast Iron |

| Insulation Class | F |

| Catalogue Download | M3JP Totally enclosed flameproof motor |

| Brand | ABB |