ABB ACS880 supply units air-cooled drivesACS880-304-1820A-5+A004+A018

ABB’s all-compatible drives are designed to provide customers across industries and applications with unprecedented levels of compatibility and flexibility. The ACS880 drive modules are optimized for panel building. They are customized to meet the particular needs of specific industries, such as oil and gas, mining, metals, chemicals, cement, power plants, material handling, pulp and paper, sawmills, marine, water and wastewater, food and beverage, and automotive. They can control a wide range of applications, including cranes, extruders, winches, winders, conveyors, mixers, compressors, centrifuges, test benches, elevators, extruders, pumps and fans.Reliability and consistent high quality The ACS880 drives are designed for customers who value high quality and robustness in their applications. They have coated boards as standard, making the ACS880 suitable for harsh conditions. Additionally, every ACS880 drive is factory-tested at full load to ensure maximum reliability. The tests include performance and all protective functions. High performance, safety and configurability The ACS880 offers the highest level of performance. The drives are equipped with ABB’s signature Direct Torque Control (DTC), which provides precise speed and torque control for all applications and supports virtually any type of motor. The extensive ACS880 offering includes wall_x0002_mounted drives, drive modules and cabinet-built drives, as well as low harmonic and regenerative variants. The ACS880 has all the essential features built-in reducing the time required for engineering, installation and commissioning. A wide range of options are also available to optimize the drive for different requirements, including certified, integrated safety features.

The ACS880 industrial drive modules are designed for cabinet installation,

with optimized location of the power terminals and wheels for easy maneuvering.

A wide selection of module variants and options, including extensive programming

and connectivity, make the ACS880 suitable for various different requirements and

applications.

Optimized for cabinet assembly

• Flexible mounting directions and product configurations

• Side-by-side mounting

• Power terminal locations designed for optimal and

compact cabinet layout

• High power modules with wheels for easy maneuvering

• Possibility for flange (push through) mounting

• Mechanical kits for easy cabinet assembly

Ease of engineering and use

ACS880-304-3640A-5+A004+A018

ACS880-304-5470A-5+A004+A018

ACS880-304-0570A-7+A018

ACS880-304-0820A-7+A018

ACS880-304-1060A-7+A018

ACS880-304-1520A-7+A018

ACS880-304-2280A-7+A018

ACS880-304-3040A-7+A018

ACS880-304-3800A-7+A018

ACS880-304-4560A-7+A018

ACS880-304-0760A-7+A004+A018

ACS880-304-1060A-7+A004+A018

ACS880-304-1520A-7+A004+A018

ACS880-304-2130A-7+A004+A018

ACS880-304-3040A-7+A004+A018

ACS880-304-4560A-7+A004+A018

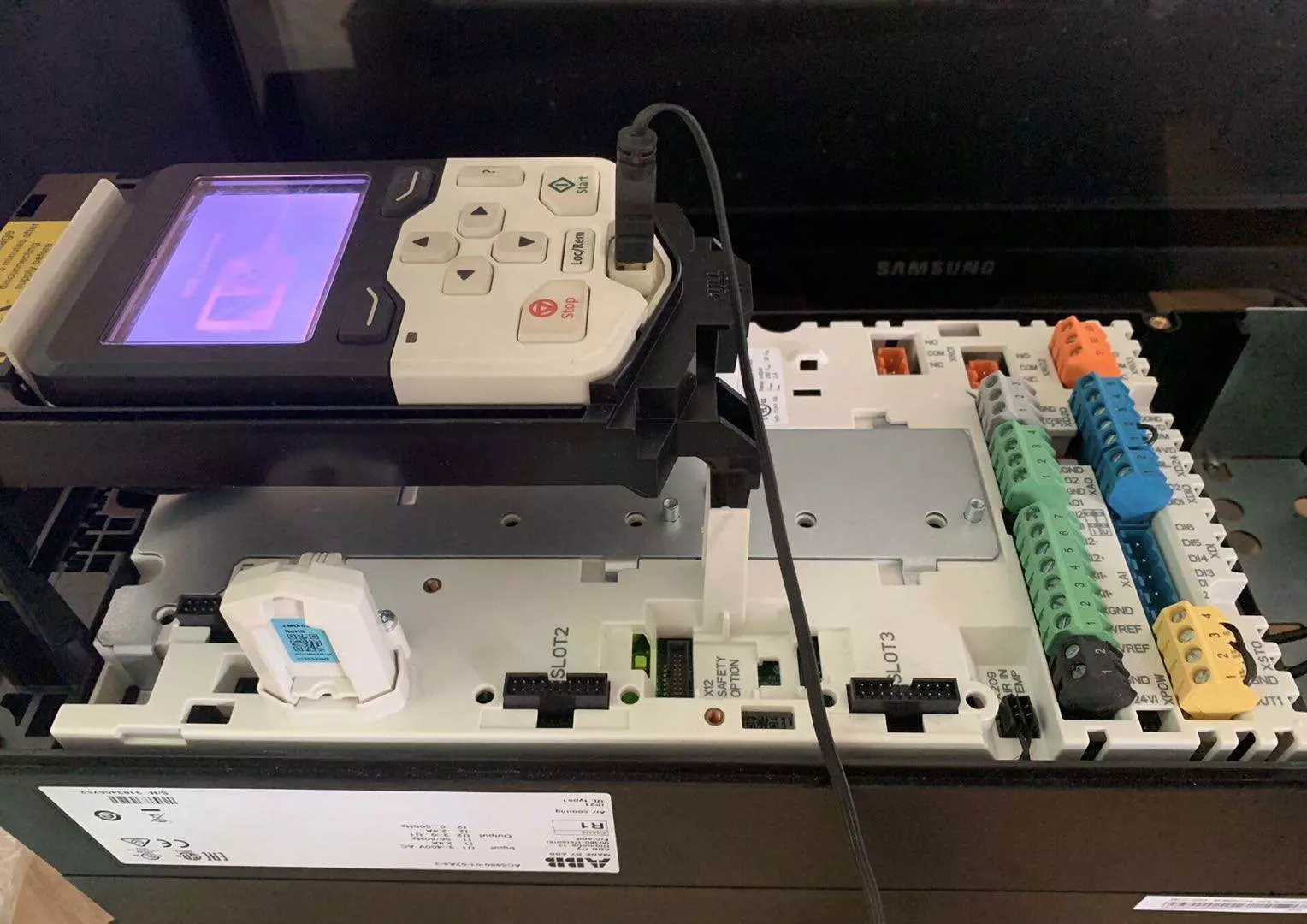

• Multilingual control panel with clear display

• Graphical PC tools for engineering, commissioning and

maintenance

• Minimized engineering and installation effort with

integrated features and components

• Extensive selection of support material and tools for

engineering

• Virtual commissioning

Smarter solutions with

drive-based functional safety

• Safe Torque Off built-in as standard

• Optional safety modules for extended safety functions

• Encoderless safe speed detection

• Highest level of machinery safety, SIL 3 / PL e

• TÜV certified

Comprehensive connectivity

• Communication with all major automation networks

• Remote monitoring

• Mobile connectivity

• Integration tools for various PLCs

• Extensive selection of support material and tools for

engineering

• Virtual commissioning

Smarter solutions with

drive-based functional safety

• Safe Torque Off built-in as standard

• Optional safety modules for extended safety functions

• Encoderless safe speed detection

• Highest level of machinery safety, SIL 3 / PL e

• TÜV certified

Comprehensive connectivity

• Communication with all major automation networks

• Remote monitoring

• Mobile connectivity

• Integration tools for various PLCs

Minimized downtime

• Robust, long lifetime design for maximum reliability

• Coated circuit boards for harsh conditions

• Removable memory unit for fast drive replacement

• Each drive factory tested at full load

• Nine-year maintenance interval

• Worldwide service and support

• Advanced features for analyzing and resolving issues

Global compatibility with various demands

• Global product approvals, e.g. CE, UL, cUL, CSA,

marine certifications, ATEX

• Support for various motor types

• Low harmonic content

• Capable of power regeneration

Premium control and programmability

• Direct Torque Control (DTC) for precise control

• Speed, torque and position control as well as

synchronizing

• Extensive parameter-based programming

• Adaptive programming as standard

• Drive-based PLC programmability (IEC 61131-3) for

fully customized solutions

Optimized mechanical design for

cabinet assembly

ACS880 drive modules have been optimized

for assembly into the customer’s own cabinets

to ensure high quality and compact installation

at minimal cost. High power modules have wheels

for easy maneuvering, and the power terminal

locations have been designed for optimal and

compact cabinet layout. Side-by-side mounting

reduces the required cabinet space.

For harsh environments, flange mounting (push

through) with UL (NEMA) Type 12 / IP55 back side

protection is offered for complete drive modules.

In flange mounting, the control electronics are

separated from the cooling airflow for better

thermal management and higher reliability.

Flexible mounting and cabling directions

enable adaptation to various cabinet enclosures.

All the complete ACS880 drive modules have

UL (NEMA) Type Open / IP20 enclosure class to

minimize engineering and assembly effort, as well

ACS880-204-1050A-7

ACS880-204-1570A-7

ACS880-204-2070A-7

ACS880-204-3080A-7

ACS880-304-0080A-5+A003

ACS880-304-0170A-5+A003

ACS880-304-0330A-5+A003

ACS880-304-0490A-5+A003

ACS880-304-0650A-5+A003

ACS880-304-0980A-5+A003

ACS880-304-0650A-5+A018

ACS880-304-0980A-5+A018

ACS880-304-1210A-5+A018

ACS880-304-1820A-5+A018

ACS880-304-2730A-5+A018

ACS880-304-3640A-5+A018

ACS880-304-4560A-5+A018

ACS880-304-5470A-5+A018

ACS880-304-0910A-5+A004+A018

ACS880-304-1210A-5+A004+A018

ACS880-304-1820A-5+A004+A018

ACS880-304-2430A-5+A004+A01

Support for cabinet assembly

A large variety of support material is available

for making cabinet assembly, planning, and

implementation as straightforward and rapid

as possible. Cabinet assembly accessories help

shorten engineering and assembly time, and

help to reduce the risk of errors.

A wide selection of both mechanical and

electrical installation accessories are offered

for high power modules. These accessories are

available allowing full design to install the modules

into customer enclosures. Additionally, ABB

authorized and registered system integrators and

panel builders can offer their assistance.

Optimized mechanical design for

cabinet assembly

ACS880 drive modules have been optimized

for assembly into the customer’s own cabinets

to ensure high quality and compact installation

at minimal cost. High power modules have wheels

for easy maneuvering, and the power terminal

locations have been designed for optimal and

compact cabinet layout. Side-by-side mounting

reduces the required cabinet space.

For harsh environments, flange mounting (push

through) with UL (NEMA) Type 12 / IP55 back side

protection is offered for complete drive modules.

In flange mounting, the control electronics are

separated from the cooling airflow for better

thermal management and higher reliability.

Flexible mounting and cabling directions

enable adaptation to various cabinet enclosures.

All the complete ACS880 drive modules have

UL (NEMA) Type Open / IP20 enclosure class to

minimize engineering and assembly effort, as well

ACS880-204-1050A-7

ACS880-204-1570A-7

ACS880-204-2070A-7

ACS880-204-3080A-7

ACS880-304-0080A-5+A003

ACS880-304-0170A-5+A003

ACS880-304-0330A-5+A003

ACS880-304-0490A-5+A003

ACS880-304-0650A-5+A003

ACS880-304-0980A-5+A003

ACS880-304-0650A-5+A018

ACS880-304-0980A-5+A018

ACS880-304-1210A-5+A018

ACS880-304-1820A-5+A018

ACS880-304-2730A-5+A018

ACS880-304-3640A-5+A018

ACS880-304-4560A-5+A018

ACS880-304-5470A-5+A018

ACS880-304-0910A-5+A004+A018

ACS880-304-1210A-5+A004+A018

ACS880-304-1820A-5+A004+A018

ACS880-304-2430A-5+A004+A01

Support for cabinet assembly

A large variety of support material is available

for making cabinet assembly, planning, and

implementation as straightforward and rapid

as possible. Cabinet assembly accessories help

shorten engineering and assembly time, and

help to reduce the risk of errors.

A wide selection of both mechanical and

electrical installation accessories are offered

for high power modules. These accessories are

available allowing full design to install the modules

into customer enclosures. Additionally, ABB

authorized and registered system integrators and

panel builders can offer their assistance.

All-compatible user interface saves

commissioning and learning time

The ACS880 is part of ABB’s all-compatible

drives portfolio. Other drives in this portfolio

are the ACS380, ACS480 and ACS580.

These drives share the same easy-to-use PC

tools and multilingual control panels. To further

enhance the user experience they also have the

same parameter structure, saving learning and

commissioning time.

The drives also share the same communication

option modules, simplifying the use of the drives

and spare parts required.

Simplicity at your fingertips as standard

The control panel’s assistant helps you setup the

ACS880-204-006A6-5

ACS880-204-0015A-5

ACS880-204-0029A-5

ACS880-204-0041A-5

ACS880-204-0077A-5

ACS880-204-0210A-5

ACS880-204-0400A-5

ACS880-204-0530A-5

ACS880-204-0730A-5

ACS880-204-1040A-5

ACS880-204-1420A-5

ACS880-204-2120A-5

ACS880-204-2800A-5

ACS880-204-4150A-5

ACS880-204-0310A-7

ACS880-204-0370A-7

ACS880-204-0540A-7

ACS880-204-0720A-7

easy navigation in multiple languages.

The PC tool for commissioning and configuration

provides extensive drive monitoring capabilities,

quick access to drive settings, as well as a graphical

interface for configuring safety functions, visual

control diagrams, and direct links to user manuals.

Built-in features simplify ordering

and installation

All ACS880 drives have an internal choke for

harmonic filtering, a Modbus RTU fieldbus

interface, and Safe Torque Off functionality as

standard. Other built-in features, standard or

optional, include EMC filters, brake choppers, du/

dt filters, low harmonic or regenerative

functionality, various I/O extensions,

communication protocol adapters, and functional

safety modules.

The built-in features shorten engineering and

installation time as well as reduce the risk of errors.

As a result, the total cost is lower and the whole

drive system is more compact.

Engineering support

ABB provides an extensive selection of support

material and tools to help in engineering, such as:

• Drive sizing tools, e.g. DriveSize

• Step-by-step installation instructions

• E-learning

• Safety circuit design tools

• EPLAN P8 macros

• Selection tool for choosing external components,

e.g. fuses and circuit breakers

• Dimensional (2D and 3D) and electrical drawings

• Application guides

• Drive installation and configuration videos

These tools and support from our experts ensure

that the drive system can be set up easily and

reliably.

Advanced features for analyzing and

resolving issues

The ACS880 has timers and counters that can be

configured to remind you when the drive or process

equipment needs maintenance.

Accurate and reliable diagnostic information is

available for warning and fault messages. Help

texts give detailed information about the warning

or fault. Data loggers store critical values before

and during an event. The real-time clock allows you

to see the exact times of events.

For faster remote support, all relevant drive data

and changed parameters can be saved in a single

file package that you can easily create with the

Drive Composer PC tool or by creating a QR code

with the control panel.

Global support

ABB offers worldwide support via its extensive pre and post-sales network, structured to make sure

that you have the experts you need close by, locally

and globally.

Global product approvals

The ACS880 is a global product and has all the

major global approvals, including CE, UL, cUL, EAC,

RCM and TÜV. Marine approval, ATEX and SEMI F47

are available either as standard or as an option.

Support for different motor types

The ACS880 provides reliable control for squirrel

cage, high-torque or servo-type permanent

magnet, synchronous reluctance (SynRM),

submersible and high-speed motors. Most encoder

types are supported.

Regardless of the motor type, drive commissioning

is easy, with no need for laborious manual tuning.

Low harmonic content

All ACS880 drives have an internal choke for

harmonic reduction. If lower harmonic content is

needed, an ultra-low harmonic variant is available.

The drive will produce exceptionally low harmonic

content and meet the requirements IEEE519,

IEC61000-3-12 and G5/4.

Regeneration of energy

The ACS880 offers a number of solutions for

applications where electrical braking is needed. As

standard, ACS880 drives have a flux braking feature

that provides greater deceleration by increasing

the motor flux. If this is not sufficient, the internal

brake chopper can be used together with a brake

resistor.

The most advanced solution is the ACS880

regenerative drive, which allows full, continuous

braking and can produce remarkable energy

savings.

ACS880 also supports common DC bus

configurations, where the braking energy from one

load can be utilized by other loads.

All-compatible user interface saves

commissioning and learning time

The ACS880 is part of ABB’s all-compatible

drives portfolio. Other drives in this portfolio

are the ACS380, ACS480 and ACS580.

These drives share the same easy-to-use PC

tools and multilingual control panels. To further

enhance the user experience they also have the

same parameter structure, saving learning and

commissioning time.

The drives also share the same communication

option modules, simplifying the use of the drives

and spare parts required.

Simplicity at your fingertips as standard

The control panel’s assistant helps you setup the

ACS880-204-006A6-5

ACS880-204-0015A-5

ACS880-204-0029A-5

ACS880-204-0041A-5

ACS880-204-0077A-5

ACS880-204-0210A-5

ACS880-204-0400A-5

ACS880-204-0530A-5

ACS880-204-0730A-5

ACS880-204-1040A-5

ACS880-204-1420A-5

ACS880-204-2120A-5

ACS880-204-2800A-5

ACS880-204-4150A-5

ACS880-204-0310A-7

ACS880-204-0370A-7

ACS880-204-0540A-7

ACS880-204-0720A-7

easy navigation in multiple languages.

The PC tool for commissioning and configuration

provides extensive drive monitoring capabilities,

quick access to drive settings, as well as a graphical

interface for configuring safety functions, visual

control diagrams, and direct links to user manuals.

Built-in features simplify ordering

and installation

All ACS880 drives have an internal choke for

harmonic filtering, a Modbus RTU fieldbus

interface, and Safe Torque Off functionality as

standard. Other built-in features, standard or

optional, include EMC filters, brake choppers, du/

dt filters, low harmonic or regenerative

functionality, various I/O extensions,

communication protocol adapters, and functional

safety modules.

The built-in features shorten engineering and

installation time as well as reduce the risk of errors.

As a result, the total cost is lower and the whole

drive system is more compact.

Engineering support

ABB provides an extensive selection of support

material and tools to help in engineering, such as:

• Drive sizing tools, e.g. DriveSize

• Step-by-step installation instructions

• E-learning

• Safety circuit design tools

• EPLAN P8 macros

• Selection tool for choosing external components,

e.g. fuses and circuit breakers

• Dimensional (2D and 3D) and electrical drawings

• Application guides

• Drive installation and configuration videos

These tools and support from our experts ensure

that the drive system can be set up easily and

reliably.

Advanced features for analyzing and

resolving issues

The ACS880 has timers and counters that can be

configured to remind you when the drive or process

equipment needs maintenance.

Accurate and reliable diagnostic information is

available for warning and fault messages. Help

texts give detailed information about the warning

or fault. Data loggers store critical values before

and during an event. The real-time clock allows you

to see the exact times of events.

For faster remote support, all relevant drive data

and changed parameters can be saved in a single

file package that you can easily create with the

Drive Composer PC tool or by creating a QR code

with the control panel.

Global support

ABB offers worldwide support via its extensive pre and post-sales network, structured to make sure

that you have the experts you need close by, locally

and globally.

Global product approvals

The ACS880 is a global product and has all the

major global approvals, including CE, UL, cUL, EAC,

RCM and TÜV. Marine approval, ATEX and SEMI F47

are available either as standard or as an option.

Support for different motor types

The ACS880 provides reliable control for squirrel

cage, high-torque or servo-type permanent

magnet, synchronous reluctance (SynRM),

submersible and high-speed motors. Most encoder

types are supported.

Regardless of the motor type, drive commissioning

is easy, with no need for laborious manual tuning.

Low harmonic content

All ACS880 drives have an internal choke for

harmonic reduction. If lower harmonic content is

needed, an ultra-low harmonic variant is available.

The drive will produce exceptionally low harmonic

content and meet the requirements IEEE519,

IEC61000-3-12 and G5/4.

Regeneration of energy

The ACS880 offers a number of solutions for

applications where electrical braking is needed. As

standard, ACS880 drives have a flux braking feature

that provides greater deceleration by increasing

the motor flux. If this is not sufficient, the internal

brake chopper can be used together with a brake

resistor.

The most advanced solution is the ACS880

regenerative drive, which allows full, continuous

braking and can produce remarkable energy

savings.

ACS880 also supports common DC bus

configurations, where the braking energy from one

load can be utilized by other loads.

Direct Torque Control (DTC)

ABB's state of the art motor control technology

provides precise speed and torque control, with or

without an encoder, even close to zero speed. DTC

provides reliable starts and rapid reactions to load

or line changes, and ensures smooth and

continuous operation. DTC provides optimal

control, even with sine filters.

The energy optimizer feature maximizes motor

efficiency by ensuring maximum torque per

ampere, reducing the power drawn from the

supply.

Position control and synchronizing

Position control allows to meet motion systems

demands without the need of an external position

controller. The ready-made motion functions

can be easily configured by parameters.

Additional features, such as built-in synchronized

drive to drive link and possibility for encoderless

positioning, make ACS880 position control ideal

for any axis.

Drive programming

To meet your specific application needs, you can

customize your ACS880 with an extensive range of

user-definable software settings (parameters) and

adaptive programming.

This makes fine-tuning the ready-made application

control program easy. For further customization,

drive application programming based on IEC 61131

standard is available for full PLC programmability.

IEC programming uses the same programming

environment as ABB PLCs. It is also easy to

integrate the ACS880 with PLCs and HMIs.

Adaptive programming is an easy to use

dynamic programming which allows flexible

adjustments to the ACS880 software.

IEC programming

based on IEC 61131 standard for full scale PLC

programmability is available as an option.

Flexibility and ease of cabinet assembly

The ACS880 modules have all the essential features

built-in. These standard and optional features

include a choke for harmonic filtering, brake

chopper, EMC filter, communication protocol

adapter, functional safety and I/O extension

modules. The built-in design combined with UL

(NEMA) Type Open / IP20 protection significantly

simplifies engineering.

The drive’s compact size, flexible cabling options

and versatile mounting possibilities from narrow

side-by-side to flat mounting to horizontal

mounting make it an ideal fit for almost any

enclosure. The control unit with I/O and

communication connections is mounted outside

the power module.

The flange mounting variant (-04F/04FXT) with UL

(NEMA) Type 12 / IP55 heat sink makes the drive

suitable for harsh environments. High power units

with parallel connected drive modules extends the

power range with -04XT up to 1250 HP (1200 kW)

and with -04FXT up to 2500 HP (2400 kW).

Single drive modules,

ACS880-04/04F/04XT/04FXT

• Power ratings: 275 to 2500 HP (200 to 2400 kW)

• Enclosure classes: -04: UL (NEMA) Type Open / IP20,

-04F: UL (NEMA) Type Open / IP20 [UL (NEMA) Type

12 / IP55 for heat sink side], -04XT: UL (NEMA) Type

Open / IP00(IP20 with optional shrouds), -04FXT: UL

(NEMA) Type Open / IP00 (IP20 with optional

shrouds) [UL (NEMA) Type 12 / IP55 for heat sink

side].

Ready-made packages for easy installation

The ACS880-04 high power single drive module

package includes a supply unit and a separate

inverter unit. The supply unit consists of D7T or D8T

half-controlled diode modules with thyristor

charging. Parallel connected R8i modules are

utilized in the inverter unit. The drive module

packages are ready-sized and are available as

6-pulse or 12-pulse variants.

Installing and transporting the modules is easy, as

they are equipped with wheels. Connecting the

modules to the motor cables inside the cabinet is

fast with the quick connectors. The modules can

also be easily pulled out from a cabinet without any

need for disconnecting the motor cables.

The inverter module comes equipped with a

removable fan pedestal, which makes motor

cabling easy. To further shorten the engineering

and assembly time several mechanical and

electrical accessories are available.

High power single drive module packages,

ACS880-04

• Power ratings: 600 to 2250 HP (400 to 2200 kW)

• Enclosure classes: UL (NEMA) Type Open / IP00

• Built-in choke as standard for input harmonic

reduction

• External control unit

• Speed controlled cooling fans

• Large power terminals allowing the use of a wide

range of cable sizes

• Internal du/dt filters as standard in R8i inverter

modules

ABB regenerative drive modules are optimized

for cabinet assembly. ACS880-11+P940 and

ACS880-14 frame R11 are compact and complete

drive solutions, with everything needed for

regenerative operation in cyclic or continuous

braking applications. For high power applications

ACS880-14 single drive module packages are

available.

Energy savings

With regenerative functionality, the braking energy

of the motor is returned to the drive and

distributed to the supply network so that it can be

utilized by other equipment. Compared to

mechanical or resistor braking, where braking

energy is wasted as heat, regenerative drive

operation offers significant savings in energy

consumption and cooling.

The drive reaches unity power factor. This high

power factor indicates that electrical energy is

used to its full potential.

Minimized downtime

Regenerative drives offer immunity to network

disturbances. The drive will not interrupt the

process or affect process quality in unstable supply

network conditions. The ACS880 drive’s active

supply unit is able to boost output voltage,

resulting in full motor voltage even when the supply

voltage is below nominal. Voltage boost capability

can also be utilized to overcome a voltage drop

caused by long supply or motor cables or output

filters.

Optimized cost and space

Everything needed for regenerative operation, such

as an active supply unit and low harmonic line filter

are included, and no external braking devices are

needed.

Advantages:

• Quick, easy drive installation

• Small installation footprint

• No need to add cooling to handle the heat

generated by mechanical or resistor braking

• Simplified wiring

• Less spare parts needed

Single drive modules,

ACS880-04/04F/04XT/04FXT

• Power ratings: 275 to 2500 HP (200 to 2400 kW)

• Enclosure classes: -04: UL (NEMA) Type Open / IP20,

-04F: UL (NEMA) Type Open / IP20 [UL (NEMA) Type

12 / IP55 for heat sink side], -04XT: UL (NEMA) Type

Open / IP00(IP20 with optional shrouds), -04FXT: UL

(NEMA) Type Open / IP00 (IP20 with optional

shrouds) [UL (NEMA) Type 12 / IP55 for heat sink

side].

Ready-made packages for easy installation

The ACS880-04 high power single drive module

package includes a supply unit and a separate

inverter unit. The supply unit consists of D7T or D8T

half-controlled diode modules with thyristor

charging. Parallel connected R8i modules are

utilized in the inverter unit. The drive module

packages are ready-sized and are available as

6-pulse or 12-pulse variants.

Installing and transporting the modules is easy, as

they are equipped with wheels. Connecting the

modules to the motor cables inside the cabinet is

fast with the quick connectors. The modules can

also be easily pulled out from a cabinet without any

need for disconnecting the motor cables.

The inverter module comes equipped with a

removable fan pedestal, which makes motor

cabling easy. To further shorten the engineering

and assembly time several mechanical and

electrical accessories are available.

High power single drive module packages,

ACS880-04

• Power ratings: 600 to 2250 HP (400 to 2200 kW)

• Enclosure classes: UL (NEMA) Type Open / IP00

• Built-in choke as standard for input harmonic

reduction

• External control unit

• Speed controlled cooling fans

• Large power terminals allowing the use of a wide

range of cable sizes

• Internal du/dt filters as standard in R8i inverter

modules

ABB regenerative drive modules are optimized

for cabinet assembly. ACS880-11+P940 and

ACS880-14 frame R11 are compact and complete

drive solutions, with everything needed for

regenerative operation in cyclic or continuous

braking applications. For high power applications

ACS880-14 single drive module packages are

available.

Energy savings

With regenerative functionality, the braking energy

of the motor is returned to the drive and

distributed to the supply network so that it can be

utilized by other equipment. Compared to

mechanical or resistor braking, where braking

energy is wasted as heat, regenerative drive

operation offers significant savings in energy

consumption and cooling.

The drive reaches unity power factor. This high

power factor indicates that electrical energy is

used to its full potential.

Minimized downtime

Regenerative drives offer immunity to network

disturbances. The drive will not interrupt the

process or affect process quality in unstable supply

network conditions. The ACS880 drive’s active

supply unit is able to boost output voltage,

resulting in full motor voltage even when the supply

voltage is below nominal. Voltage boost capability

can also be utilized to overcome a voltage drop

caused by long supply or motor cables or output

filters.

Optimized cost and space

Everything needed for regenerative operation, such

as an active supply unit and low harmonic line filter

are included, and no external braking devices are

needed.

Advantages:

• Quick, easy drive installation

• Small installation footprint

• No need to add cooling to handle the heat

generated by mechanical or resistor braking

• Simplified wiring

• Less spare parts needed

The “all inside” design for frames up to R11 and

mechanical installation kits for module packages

help to cut engineering and assembly time, as well

as to reduce equipment costs and the risk of errors.

The drive’s voltage boost capability can be an

advantage in motor sizing. With a higher motor

voltage, the same power is achieved with less

current, which may allow a smaller motor to be

used.

With the ACS880 regenerative drive it is possible to

compensate for low power factors of equipment

connected to the same network. This reduces the

need for additional power factor correction

equipment, including filters and large capacitor

banks. It can also help avoid penalty charges from

electrical utilities for poor power factor.

Maximized motor performance and efficiency

The drive is able to provide full motor voltage in all

conditions. ACS880 drives can regenerate 100%

current to the line continuously.

The drive features Direct Torque Control (DTC)

as standard, making it suitable for very demanding

applications. DTC provides precise speed and

torque control for maximum motor performance

and efficiency.

ACS880-11+P940 and ACS880-14 frame R11

• Power ratings: 3 to 450 HP (2.2 to 400 kW)

• Enclosure classes: UL (NEMA) Type Open / IP20, in

flange mounting (ACS880-11) heat sink side UL

(NEMA) Type 12 / IP55

The “all inside” design for frames up to R11 and

mechanical installation kits for module packages

help to cut engineering and assembly time, as well

as to reduce equipment costs and the risk of errors.

The drive’s voltage boost capability can be an

advantage in motor sizing. With a higher motor

voltage, the same power is achieved with less

current, which may allow a smaller motor to be

used.

With the ACS880 regenerative drive it is possible to

compensate for low power factors of equipment

connected to the same network. This reduces the

need for additional power factor correction

equipment, including filters and large capacitor

banks. It can also help avoid penalty charges from

electrical utilities for poor power factor.

Maximized motor performance and efficiency

The drive is able to provide full motor voltage in all

conditions. ACS880 drives can regenerate 100%

current to the line continuously.

The drive features Direct Torque Control (DTC)

as standard, making it suitable for very demanding

applications. DTC provides precise speed and

torque control for maximum motor performance

and efficiency.

ACS880-11+P940 and ACS880-14 frame R11

• Power ratings: 3 to 450 HP (2.2 to 400 kW)

• Enclosure classes: UL (NEMA) Type Open / IP20, in

flange mounting (ACS880-11) heat sink side UL

(NEMA) Type 12 / IP55

Harmonic distortions can disturb or even damage

sensitive equipment connected in the same

environment. Harmonics also cause additional

losses in the network.

The ACS880-31+P940 and ACS880-34 frame R11

are compact, complete drive modules with

harmonic mitigation built-in. For high power

solutions, the ACS880-34 single drive module

packages are available.

Clean supply network

Our ultra-low harmonic drive produces

exceptionally low harmonic content and exceeds

the requirements of harmonic specifications

including IEEE 519 and G5/4. Compared to a

conventional drive, the harmonic content is

reduced by up to 97%. The total harmonic current

distortion is typically <3% in nominal situations

with an undistorted network.

Minimized downtime

ABB’s ultra-low harmonic drive offers immunity to

network disturbances. The drive will not interrupt

the process or affect process quality in unstable

supply network conditions. The ACS880 drive's

active supply unit is able to boost the output

voltage resulting in full motor voltage even when

the supply voltage is below nominal. This ensures

reliable operation in weak networks. This voltage

boost capability can also be utilized to overcome

voltage drops caused by long supply or motor

cables

Optimized cost and space

The compact ACS880 low harmonic drive solution

has harmonic mitigation built-in. This includes an

active supply unit and low harmonic line filter.

There is no need for external filters, multi-pulse

arrangements or special transformers, resulting in

significant savings in space, time and cost.

Oversizing cables, transformers and other

distribution equipment due to harmonic current

overheating can often be ignored when using the

ACS880 low harmonic drive.

The drive’s voltage boost capability can be an

advantage in motor sizing. With a higher motor

voltage, the same power is achieved with less

current, which improves motor efficiency

and may allow a smaller motor to be used.

Maximized motor performance and efficiency

The drive is able to provide full motor voltage even

if the supply voltage fluctuates. It features Direct

Torque Control (DTC) as standard, making it

suitable for very demanding applications. DTC

provides precise speed and torque control for

maximum motor performance and motor

efficiency.

Ultra-low harmonic single drive modules,

ACS880-31+P940 and ACS880-34 frame R11

• Power ratings: 3 to 450 HP (2.2 to 400 kW)

• Enclosure classes: UL (NEMA) Type Open / IP20, in

flange mounting (ACS880-31) heat sink side UL

(NEMA) Type 12 / IP55

The module selection for building multidrive

configurations includes inverter, diode supply, IGBT

supply, regenerative rectifier, brake and DC-DC

converter units. Their modular design and side-by side mounting make installation fast and easy.

Modules with bigger frame sizes are equipped with

wheels so they can easily be moved in or out of the

cabinet for maintenance purposes. This concept

also allows pre-installation of the power cables

inside the empty cabinet.

Multidrives can be used wherever several motors

form part of a single process. With a compact

module design and high power density, the single

supply and DC bus arrangement with multiple

inverters provides many advantages:

• Savings in cabling, installation and maintenance

costs

• Reduced component count and increased

reliability

• Reduced line power and line currents. As the

energy circulates over the common DC bus, all

energy is not taken from the supply network.

Energy circulation can be used for motor-to motor braking without the need for a braking

chopper or regenerative supply unit.

Inverter units (INU)

Inverter units are DC supplied and have built-in

capacitors for smoothing the DC voltage.

The electrical connection to the common DC bus is

fuse protected. An optional switch can be selected

to disconnect the whole drive unit from the DC bus.

Diode supply units (DSU)

A diode supply unit is used in non-regenerative

drive systems to convert three-phase AC voltage to

DC voltage. Two types of diode supply unit are

available: an uncontrolled 6-pulse diode supply unit

(D6D to D8D) and a half-controlled diode supply

unit with thyristor charging (D7T and D8T). The DxT

modules can be connected parallel and are able to

charge the inverters without external components.

Simple and cost-efficient installation

The high-efficient liquid cooling removes the need

for air-conditioning in the installation rooms,

bringing the installation and operation costs down.

As there is no need for additional air conditioning

devices or air ducts, the installation is significantly

simplified.

The used coolant type is Antifrogen® L, by Clariant

International Ltd, cooling liquid with glycol and

inhibitor. It is a ready-made, commercially available

mix, which enables easy commissioning and

prevents the risk of errors in coolant selection.

Wide selection of drive module products

Covering a wide power range with a very small

footprint, the liquid-cooled ACS880 is available for

single and multidrive purposes. The product family

includes compact diode supply, IGBT supply,

inverter units and DC/DC converters. Optional

stand-alone liquid cooling units are offered for

cooling the modules. All piping and heat

ACS880-904-0600A-5

ACS880-904-0900A-5

ACS880-904-1180A-5

ACS880-904-1770A-5

ACS880-904-2310A-5

ACS880-904-3460A-5

ACS880-904-0600A-7

ACS880-904-0900A-7

ACS880-904-1180A-7

ACS880-904-1770A-7

ACS880-904-2310A-7

ACS880-904-3460A-7

ACS880-604-0260-5

ACS880-604-0400-5

ACS880-604-0800-5

ACS880-604-1200-5

ACS880-604-1600-5

ACS880-604-2000-5

ACS880-604-2400-5

ACS880-604-0400-7

ACS880-604-0800-7

ACS880-604-1200-7

ACS880-604-1600-7

ACS880-604-2000-7

ACS880-604-2400-7

ACS880-604-0630-5

ACS880-604-0940-5

ACS880-604-1260-5

ACS880-604-1880-5

ACS880-604-2830-5

ACS880-604-3770-5

ACS880-604-4710-5

ACS880-604-0870-7

ACS880-604-1300-7

ACS880-604-1730-7

ACS880-604-2600-7

ACS880-604-3900-7

ACS880-604-5200-7

ACS880-604-6500-7

In addition, ABB offers an extensive selection of

electrical and mechanical installation accessories,

including piping components. These minimize

cabinet engineering and assembly effort and

ensure a safe, tested cabinet design.

Liquid-cooled modules, ACS880-x04LC

• Power ratings:

Diode supply units (DSU): 745 to 3466 kW

IGBT supply units (ISU): 430 to 3502 kVA

Inverter units (INU): 300 to 3300 HP (250 to 3000

kW)

Brake choppers: 54 to 714 kW

DC/DC converters: 400 to 1800 A

• Enclosure class: UL (NEMA) Type Open / IP00

• 3-phase inverter modules with internal

du/dt filters as standard

• Quick connectors for motor cable output

connection

• Enclosure class: UL (NEMA) Type 12 / IP54

• Stand-alone cabinet with cooling pipe

connections on the right side

• Built-in cabinet heater

• Heat exchanger for industrial cooling water

• Fulfills marine requirements

• Single pump and two pump versions

• Redundant pump version

• Different piping solutions and sea water heat

exchanger available as engineered variants

Harmonic distortions can disturb or even damage

sensitive equipment connected in the same

environment. Harmonics also cause additional

losses in the network.

The ACS880-31+P940 and ACS880-34 frame R11

are compact, complete drive modules with

harmonic mitigation built-in. For high power

solutions, the ACS880-34 single drive module

packages are available.

Clean supply network

Our ultra-low harmonic drive produces

exceptionally low harmonic content and exceeds

the requirements of harmonic specifications

including IEEE 519 and G5/4. Compared to a

conventional drive, the harmonic content is

reduced by up to 97%. The total harmonic current

distortion is typically <3% in nominal situations

with an undistorted network.

Minimized downtime

ABB’s ultra-low harmonic drive offers immunity to

network disturbances. The drive will not interrupt

the process or affect process quality in unstable

supply network conditions. The ACS880 drive's

active supply unit is able to boost the output

voltage resulting in full motor voltage even when

the supply voltage is below nominal. This ensures

reliable operation in weak networks. This voltage

boost capability can also be utilized to overcome

voltage drops caused by long supply or motor

cables

Optimized cost and space

The compact ACS880 low harmonic drive solution

has harmonic mitigation built-in. This includes an

active supply unit and low harmonic line filter.

There is no need for external filters, multi-pulse

arrangements or special transformers, resulting in

significant savings in space, time and cost.

Oversizing cables, transformers and other

distribution equipment due to harmonic current

overheating can often be ignored when using the

ACS880 low harmonic drive.

The drive’s voltage boost capability can be an

advantage in motor sizing. With a higher motor

voltage, the same power is achieved with less

current, which improves motor efficiency

and may allow a smaller motor to be used.

Maximized motor performance and efficiency

The drive is able to provide full motor voltage even

if the supply voltage fluctuates. It features Direct

Torque Control (DTC) as standard, making it

suitable for very demanding applications. DTC

provides precise speed and torque control for

maximum motor performance and motor

efficiency.

Ultra-low harmonic single drive modules,

ACS880-31+P940 and ACS880-34 frame R11

• Power ratings: 3 to 450 HP (2.2 to 400 kW)

• Enclosure classes: UL (NEMA) Type Open / IP20, in

flange mounting (ACS880-31) heat sink side UL

(NEMA) Type 12 / IP55

The module selection for building multidrive

configurations includes inverter, diode supply, IGBT

supply, regenerative rectifier, brake and DC-DC

converter units. Their modular design and side-by side mounting make installation fast and easy.

Modules with bigger frame sizes are equipped with

wheels so they can easily be moved in or out of the

cabinet for maintenance purposes. This concept

also allows pre-installation of the power cables

inside the empty cabinet.

Multidrives can be used wherever several motors

form part of a single process. With a compact

module design and high power density, the single

supply and DC bus arrangement with multiple

inverters provides many advantages:

• Savings in cabling, installation and maintenance

costs

• Reduced component count and increased

reliability

• Reduced line power and line currents. As the

energy circulates over the common DC bus, all

energy is not taken from the supply network.

Energy circulation can be used for motor-to motor braking without the need for a braking

chopper or regenerative supply unit.

Inverter units (INU)

Inverter units are DC supplied and have built-in

capacitors for smoothing the DC voltage.

The electrical connection to the common DC bus is

fuse protected. An optional switch can be selected

to disconnect the whole drive unit from the DC bus.

Diode supply units (DSU)

A diode supply unit is used in non-regenerative

drive systems to convert three-phase AC voltage to

DC voltage. Two types of diode supply unit are

available: an uncontrolled 6-pulse diode supply unit

(D6D to D8D) and a half-controlled diode supply

unit with thyristor charging (D7T and D8T). The DxT

modules can be connected parallel and are able to

charge the inverters without external components.

Simple and cost-efficient installation

The high-efficient liquid cooling removes the need

for air-conditioning in the installation rooms,

bringing the installation and operation costs down.

As there is no need for additional air conditioning

devices or air ducts, the installation is significantly

simplified.

The used coolant type is Antifrogen® L, by Clariant

International Ltd, cooling liquid with glycol and

inhibitor. It is a ready-made, commercially available

mix, which enables easy commissioning and

prevents the risk of errors in coolant selection.

Wide selection of drive module products

Covering a wide power range with a very small

footprint, the liquid-cooled ACS880 is available for

single and multidrive purposes. The product family

includes compact diode supply, IGBT supply,

inverter units and DC/DC converters. Optional

stand-alone liquid cooling units are offered for

cooling the modules. All piping and heat

ACS880-904-0600A-5

ACS880-904-0900A-5

ACS880-904-1180A-5

ACS880-904-1770A-5

ACS880-904-2310A-5

ACS880-904-3460A-5

ACS880-904-0600A-7

ACS880-904-0900A-7

ACS880-904-1180A-7

ACS880-904-1770A-7

ACS880-904-2310A-7

ACS880-904-3460A-7

ACS880-604-0260-5

ACS880-604-0400-5

ACS880-604-0800-5

ACS880-604-1200-5

ACS880-604-1600-5

ACS880-604-2000-5

ACS880-604-2400-5

ACS880-604-0400-7

ACS880-604-0800-7

ACS880-604-1200-7

ACS880-604-1600-7

ACS880-604-2000-7

ACS880-604-2400-7

ACS880-604-0630-5

ACS880-604-0940-5

ACS880-604-1260-5

ACS880-604-1880-5

ACS880-604-2830-5

ACS880-604-3770-5

ACS880-604-4710-5

ACS880-604-0870-7

ACS880-604-1300-7

ACS880-604-1730-7

ACS880-604-2600-7

ACS880-604-3900-7

ACS880-604-5200-7

ACS880-604-6500-7

In addition, ABB offers an extensive selection of

electrical and mechanical installation accessories,

including piping components. These minimize

cabinet engineering and assembly effort and

ensure a safe, tested cabinet design.

Liquid-cooled modules, ACS880-x04LC

• Power ratings:

Diode supply units (DSU): 745 to 3466 kW

IGBT supply units (ISU): 430 to 3502 kVA

Inverter units (INU): 300 to 3300 HP (250 to 3000

kW)

Brake choppers: 54 to 714 kW

DC/DC converters: 400 to 1800 A

• Enclosure class: UL (NEMA) Type Open / IP00

• 3-phase inverter modules with internal

du/dt filters as standard

• Quick connectors for motor cable output

connection

• Enclosure class: UL (NEMA) Type 12 / IP54

• Stand-alone cabinet with cooling pipe

connections on the right side

• Built-in cabinet heater

• Heat exchanger for industrial cooling water

• Fulfills marine requirements

• Single pump and two pump versions

• Redundant pump version

• Different piping solutions and sea water heat

exchanger available as engineered variants

| Rated Frequency | 50 - 60 hz |

|---|---|

| Height (mm) | 2794 |

| Width (mm) | 480 |

| Depth (mm) | 1178 |

| Type | ACS880-X04 |

| Voltage Class | 500 V |

| Frame Size | 2xD8T |

| Catalogue Download | ACS880 Catalog pdf |

| Brand | ABB |

| Country of Manufacture | Finland |