M3BP 3-Phase metric IEC frame motor 0.37/.50KW 80MD 6 3GBP083340-ACK+332 IE3

ABB process performance motors are designed to operate at the highest levels of efficiency to save energy, reduce operating costs and enable demanding motor applications to perform reliability and without unscheduled downtime. Four properties set ABB Process performance motors apart: their efficiency, reliability, use of leading-edge technology, and the virtually limitless options they provide for customization.

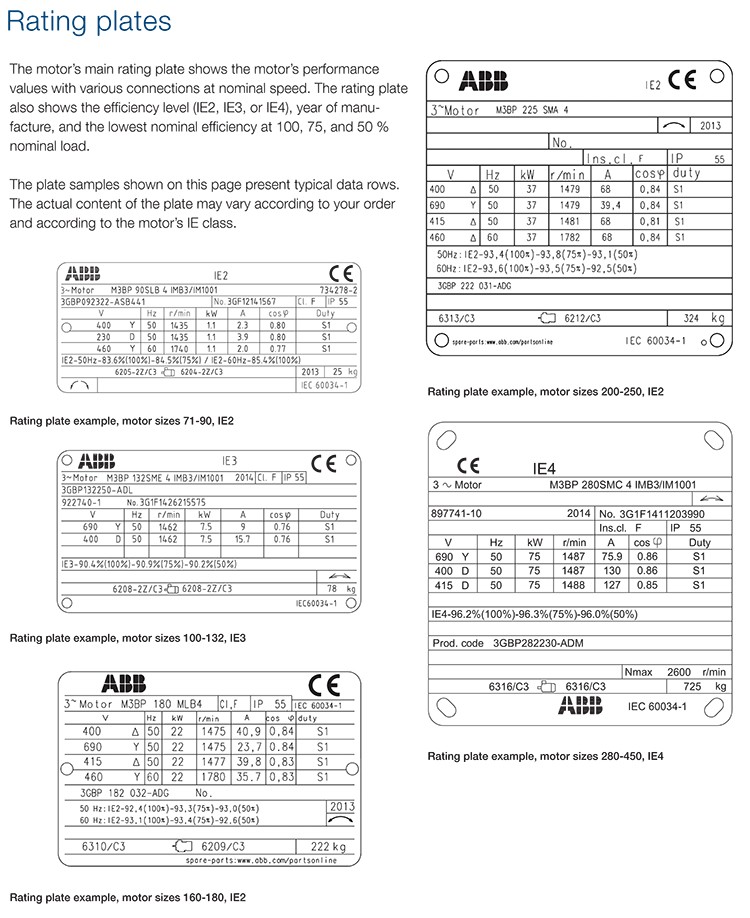

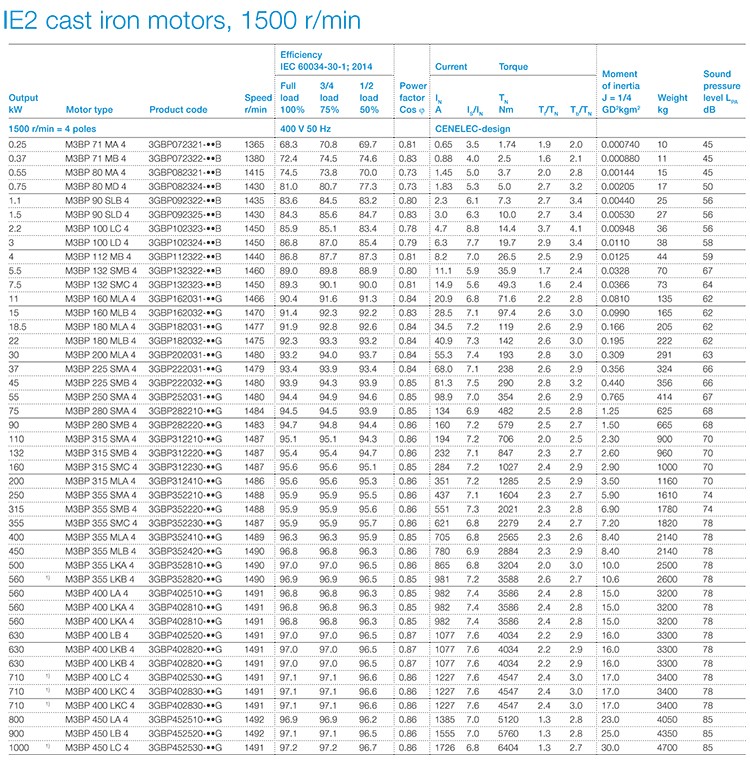

IEC 60034-30-1 covers the power range from 0.12 kW up to 1000 kW. Most of the different technical constructions of electric motors are covered as long as they are rated for direct on-line operation.

ABB determines efficiency values according to IEC 60034-2-1 using the low uncertainty method (i.e. summaration of losses), with additional load losses determined by the method of residual loss. It is good to mention and emphasize that the IEC 60034-2-1 test method, which is known as an indirect method, is technically equivalent to the test methods in the standards CSA 390-10 and IEEE 112 Method B leading to the equivalent losses and thus efficiency values.

Low voltage Process performance motors Sizes 63 to 450, 0.09 to 1000 kW, ABB M3BP Series high efficiency low voltage AC electric Motors 30KW 4P B5 flange mounted IE2.

Cast iron or die cast aluminum frame IP55 as standard Class F insulation with Class B rise 50 or 60hz operation VFD capable Warranty – 36 months from commissioning, maximum 42 months from the delivery date IE2, IE3 or IE4 efficiency classes Corrosion class C3M as standard -20 to +40°C ambient as standard

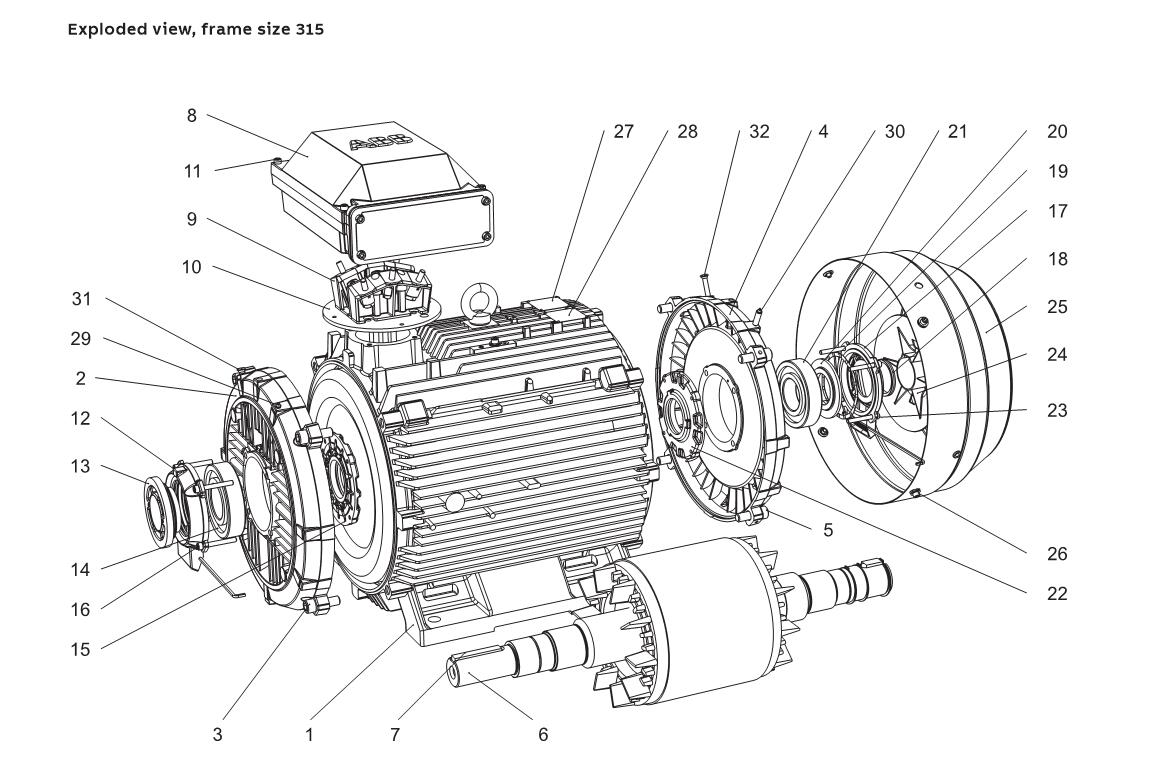

1 Stator frame 13 Valve disc with labyrinth seal, 23 Screws for bearing cover 2 End shield, D-end D-end; standard in 2-pole motors, 24 Fan 3 Screws for end shield, D-end V-ring in 4-8 pole motors 25 Fan cover 4 End shield, N-end 14 Bearing, D-end 26 Screws for fan cover 5 Screws for end shield, N-end 15 Inner bearing cover, D-end 27 Rating plate 6 Rotor with shaft 16 Screws for bearing cover 28 Lubrication plate 7 Key, D-end 17 Outer bearing cover, N-end 29 Grease nipple, D-end 8 Terminal box 18 Seal, N-end 30 Grease nipple, N-end 9 Terminal board 19 Wave spring 31 SPM nipple, D-end 10 Intermediate flange 20 Valve disc, N-end 32 SPM nipple, N-end 11 Screws for terminal box cover 21 Bearing, N-end 12 Outer bearing cover, D-end 22 Inner bearing cover, N-end

A: Foot-mounted, top-mounted terminal box

R: Foot-mounted, terminal box RHS seen from D-end

L: Foot-mounted, terminal box LHS seen from D-end

B: Flange-mounted, large flange

C: Flange-mounted, small flange (sizes 71 to 112)

H: Foot- and flange-mounted, terminal box top-mounted

J: Foot- and flange-mounted, small flange with tapped holes

S: Foot- and flange-mounted, terminal box RHS seen from D-end

T: Foot- and flange-mounted, terminal box LHS seen from D-end

V: Flange-mounted, special flange

F: Foot- and flange-mounted. Special flange

Both test methods can be used by ABB and shall be used for both Canada and the US where IEC 60034-2-1 is not recognized yet. As the world market leader, ABB offers the largest range of LV motors available.

Brake design Electromagnetic disc brakes are applied by the action of a set of springs and are released when voltage is applied to the brake coil. This means that the motor will brake automatically in case of any voltage failure, as significant safety feature.

The brake is always functional, irrespective of the mounting position of the brake motor. Axial fan, N-end Fan motors with an axial fan are available for motor sizes 71-450 and can be ordered can be ordered with variant code 183.

Common Industries Chemical, Oil & Gas Food & Beverage HVAC Marine Metal Processing Mining Pulp & Paper Rubber & Plastics Wind Common Applications Compressors Conveyors Blowers Fans Irrigation Pumps Heat Exchangers Cranes & Hoist Printing Extruders

The values here are given for 400 V, but technical data for other voltages can be found in Motor Size. Both foot-mounted and flange-mounted motors can be fitted with a silencer to reduce noise level by about 5 - 6 dB(A).

The silencer is painted blue and made of 2 mm steel sheet. The sound absorbing material is 40 mm thick polyurethane foam. On the rim there is a rubber strip for sealing on the floor. The silencer fits loosely over the motor.

X: Other rated voltage, connection or frequency, 690 V maximum.

| Type | M3BP |

|---|---|

| Voltage Class | Low Voltage < 690V |

| Feature | Process Performance |

| Motor Rotor Type | 3-Phase squirrel cage motor |

| Enclosure | Totally Enclosed Fan Cooled (TEFC) |

| IE Class | IE3 |

| Motor Power (KW) | 0.37/0.50 KW |

| Number of Poles | 6 |

| IP Rating | IP55 |

| Mounting Position | IM B3 |

| Frame Type | IEC |

| Frame Size | 80MD |

| Housing Material | Cast Iron |

| Insulation Class | F |

| Catalogue Download | M3BP Motors |

| Brand | ABB |