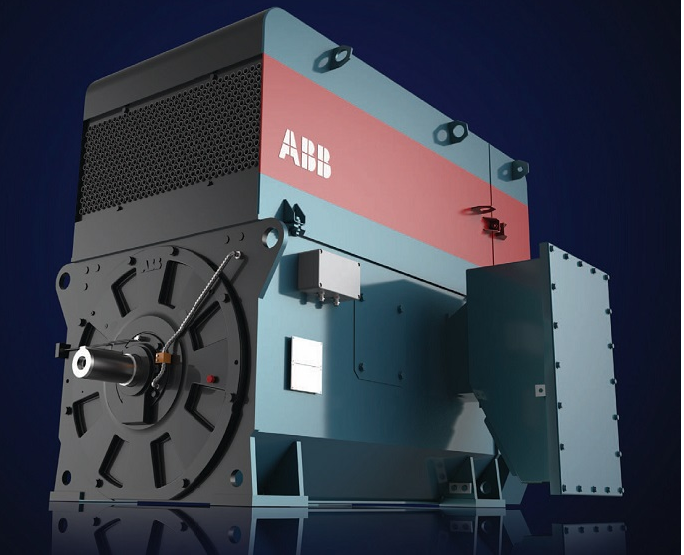

M3BM 400LKC 600 KW 6600V ABB high voltage induction motors 1491 rpm 50HZ

High voltage induction motors Technical catalog for IEC motors Rib cooled motors, type M3BM High voltage induction motors From 100 to 8000 kW High voltage process performance rib cooled motorsIP 55 – IC 411 – Insulation class F, temperature rise class B, ambient temperature 40°C. 3000 r/min = 2 poles. 3000 V. 50 Hz. 132. M3BM. Totally enclosed squirrel cage three phase high voltage motors, sizes 315 - 450, 110 to 750 kW

This catalog includes two sections: standard, and engineered. The availability of standard motors is shown in the Section 1. Standard motors up to 750 kW are available with the electrical and mechanical design characteristics as shown in this catalog. Section 2 presents ABB's high voltage engineered induction motor range up to 8000 kW. Engineered motors are made according to customers' specifications. This section includes preliminary standard technical data and drawings of engineered motors. All engineered motors are configured and optimized for each order and application.

Technical data:

Voltage (max.) 6.6 kV

Current (max.) 400 A

No of cables (max.) 1 per phase

Cross section of cables (max.) 300 mm 2 /cable

Cable gland blind gland (1 pcs)

Clearance (min.) 60 mm

Creepage (min.) 89 mm

Gross volume 44 dm 3

Usable volume 39 dm 3

Connection screws M16 (3 pcs)

Connection nuts tightening torque 40 Nm

Ground connections M12

(both in- and outside)

Weight 33 kg

Protection IP66

Standard DIN 42962 TEIL 1, A2

Dynamic short circuit current 30 kA rms x 0.25 s/

75 kA peak

Terminal boxes

Materials:

Box welded structural steel

(thickness min. 3 mm)

Cable gland plate steel

Connection screws Bronze Bz

Isolators epoxy casting resin or

polyurethane resin

Grounding pad stainless steel

The ABB NEMA cast iron Motors are ideal for serial OEMs who require a standard product with electrical and mechanical properties that do not need to be altered. These ABB NEMA Process performance cast iron Motors are designed for pump, fan and compressor applications. ABB supplies a full range of NEMA Motors. All motors are equipped as standard with an axially-locked

bearing at the D-end.

The bearing's outer ring is tightly locked between bearing's

covers and the housing fit.

Transport locking

Motors with roller bearings are fitted with a transport lock

to prevent damage to the bearings during transport. All

high voltage motors are fitted with a warning sign when the

transport lock is fitted to prevent operational damage and

alert operators.

Locking may be fitted in any other situations where the

transport conditions are considered as potentially damaging.

Basic version with deep groove ball bearings Version with roller bearings, variant code 037

If the bearing at the D-end is replaced with a roller bearing

(NU-), higher radial forces can be handled. Roller bearings are

suitable for belt drive applications.

The N-end bearing is axially free and can take the thermal

expansion. Note! NU-bearing is axially

Output power

150 to 950 HP (SF 1.5)

Frame size NEMA 506AT to 728

Number of poles 2 to 8

Voltages 2.3 to 4 kV

Frequency 60 Hz

Environment

IP55, IP56, IP65, TEFC (IC411)

Enclosure material

Cast iron

Motor type M3BM

Mounting type Horizontal

Standards IEC, NEMA, CSA

Type Description

M3BM motor catalog ratings can be re-stamped as follows. Motor construction will not be changed but a new rating plate and data sheet can be created with variant code 002. In all the below cases or their combinations, please contact ABB for correct motor size and motor data. Bearing re-lubrication intervals as shown in this catalog are valid also for re- stamped motors. Output Output can be re-stamped downwards from the catalog data. Voltage Voltage can be re-stamped downwards up to 10% from the motor nominal voltage in the catalogue. Motor output has to be de-rated so that the motor absolute temperatures will not be higher compared to catalog data. Ambient temperature Motor can be de-rated to higher ambient temperature. Maximum ambient temperature is 55 °C. The output has to be de-rated so that motor's absolute temperatures will not be higher than the catalog data. Altitude Motor can be de-rated to higher altitudes than standard 1000 meters above sea level. There are different maximum altitude limits for different motors depending on voltage level. The motor output has to be de-rated so that the absolute temperatures of the motor will not be higher than the catalog data.

Engineered motors Squirrel cage three phase high voltage motors, Up to 8000 kW Stator Material Cast iron EN-GJL-250 EN 1561 Paint colour shade Blue, Munsell 8B 4.5/3.25 / NCS 4822 B05G / RAL 5014 Paint thickness Two-pack epoxy paint, thickness ≥ 180 µm Bearing end shields Material Cast iron EN-GJL-200 SFS-EN 1561 Paint colour shade Blue, Munsell 8B 4.5/3.25 / NCS 4822 B05G / RAL 5014 Paint thickness Two-pack epoxy paint, thickness ≥ 180 µm Bearings D-end 2 pole 6316M/C3 6316M/C3 6317M/C3 6317M/C3 4-8 pole 6319/C3 6322/C3 6324/C3 6326M/C3 N-end 2 pole 6316M/C3 6316M/C3 6317M/C3 6317M/C3 4-8 pole 6316/C3 6316/C3 6319/C3 6322/C3 Axially-locked Inner bearing cover As standard, locked at D-end bearings Bearing seal As standard, labyrinth seal in both ends. Lubrication Regreasable bearings Regreasing nipples M10x1 DIN 71412 A SPM-nipples As standard Rating and Material Stainless steel, EN 10088, thickness 0.5 mm. lubrication plate Terminal box Frame material Structural steel S235JRG2-EN-10025, thickness 3 mm. Cover material Structural steel S235JRG2-EN-10025, thickness 3 mm. Cover screws material Blue passivated. Connections Cable entries Blind gland plate. Terminals 3 terminals for connection with cable lugs (not included) Grounding locations on frame and terminal box (in- and outside) Fan Material Glass reinforced polypropylene, aluminum, steel or glass reinforced polyamide fan with metal hub. Direction of rotation / fans (IC411) – glass reinforced polypropylene bidirectional – aluminum bidirectional – steel bidirectional – glass reinforced polyamide fan unidirectional. Fan cover Material Steel Paint colour shade Blue, Munsell 8B 4.5/3.25 / NCS 4822 B05G / RAL 5014P IP55, higher protection as option.irons used for AMI and NMI motors are: IC01 / IP24 This weather-protected motor has a shaft-mounted cooling fan located inside the housing. The design of the motor reduces the ingress of rain, snow and airborne particles into the electrical parts. On the air intake path this is achieved by ensuring that the average velocity does not exceed 3 m/s, allowing any heavier particles to settle. The design of air intake path includes three acute changes in excess of 90 degrees to further reduce the flow rate to the optimum level. The motor is protected against splashing water from any direction. IC611 / IP55 In this design the fully enclosed motor has an air-to-air heat exchanger mounted on the motor. Shaft mounted fans are fitted both inside and outside of the casing to supply the inside and outside cooling circuits respectively. The motor is protected against dust and splashing water from any direction. IC81W / IP55 This fully enclosed motor is fitted with an air-to-water heat exchanger. A shaft mounted fan is fitted inside the casing to supply the internal cooling circuit. Motor is protected against dust and splashing water from any direction. The terminal boxes have a protection of at least IP55. IC31 / IP55 This version is fitted with an inlet and outlet pipe to use remote cooling air. Essentially this is the AMI motor frame without any upper cover. The motor is protected against dust and splashing water from any direction. IC01 IC01 with asymmetric inside air circulation

| Type | M3BM |

|---|---|

| Voltage Class | 6600 V |

| Feature | Rib cooled motors |

| Motor Rotor Type | 3-Phase squirrel cage motor |

| Enclosure | Totally Enclosed Fan Cooled (TEFC) |

| IE Class | IE2 |

| Motor Power (KW) | 600 KW |

| Number of Poles | 4 |

| IP Rating | IP55 |

| Mounting Position | IM B3 |

| Frame Type | IEC |

| Frame Size | 400LKC |

| Housing Material | Welded Steel |

| Insulation Class | F |

| Brand | ABB |

| Country of Manufacture | China |

| Catalogue Download | ABB motors catalogue |