With the rapid development of industrial automation technology, palletizing robots have become an important symbol of automated production in enterprises, especially in simple and heavy jobs such as packaging, handling, and logistics, which require a large amount of labor.

With the continuous expansion of the production scale of the enterprise and the continuous improvement of the automation level, higher requirements are placed on the work efficiency of the palletizing robot, and the palletizing robot is required to operate stably and reliably on the predetermined trajectory. Therefore, the trajectory planning of the palletizing robot is required. The quality of the robot is more and more important to the stability of the robot and the operation of colleges and universities.

The packaging barrel palletizing robot is one of the more critical pieces of equipment on the packaging barrel assembly line. Its main function is to achieve accurate and tidy placement of packaging objects in a fixed area. Recently, the ABB palletizing robot produced ABB was put into use in a paint factory in Henan, which greatly solved the problem of large output and high labor costs in the factory. The following is a brief introduction to the advantages, characteristics, and technical parameters of the palletizing robot in the operation of palletizing and barreling coatings:

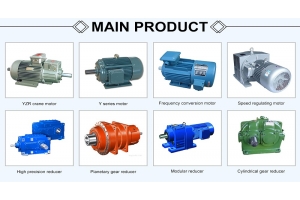

1. The palletizing robot is a flexible joint robot that completes automatic stacking tasks through the coordinated motion of multiple axes. Each arm is directly driven by a servo motor and a reducer, which effectively improves the motion efficiency of the robot, and the acceleration curve of the robot is smoother. The robot is more stable during the movement process, which effectively improves the positioning accuracy of the robot to carry the packaging barrel.

2. The whole area is small, the operating cost is low, about 700 barrels can be coded per hour, and it is digitally placed according to the required number of layers to facilitate transportation and storage.

3. The entire equipment can be easily operated by only one person, which reduces the labor intensity of employees and the staffing of the entire production line.

4. The main components are made of high-quality products at home and abroad, which are suitable for palletizing and stacking operations in the production enterprises of barreled materials such as coatings, edible oil, and lubricating oil, paint, and barreled water.

5. Long service life, low failure rate, durable and sturdy body.

6. The bottle lifting and clamping system is an adjustable structure, high, low, loose, tight, and no withering, can adapt to different bottle types, will not hurt the bottle mouth and shrink film, will not drop the bottle, low gas consumption and stable operation.

The main technical parameters:

Adapt to pallets: 850x850 to 1600x1600 mm

Palletizing capacity: about 700 barrels/hour

Applicable products: Tietong, plastic barrels, etc.

Pallet height: optional according to demand

Compressed air: 0.12M3/min, 6bar

Motor configuration: 380V/50Hz, 8kw

Equipment weight: 1.2T