ACS800-07P-0440-7+P901 ABB Variable Frequency Drive 3ABD00020455-0001

General items: sales of industrial automatic control system devices; sales of intelligent power transmission and distribution and control equipment; sales of electrical equipment; sales of mechanical and electrical equipment; sales of electronic products; sales of electronic equipment; sales of communication equipment; sales of optical communication equipment; sales of mobile communication equipment; Sales of household appliances spare parts; sales of instruments and meters; sales of mechanical equipment; electronic components; hardware products; sales of photovoltaic equipment and components; sales of pumps and vacuum equipment; sales of valves and cocks; sales of mechanical parts and components; sales of electrical accessories ; Power facilities and equipment sales; wire and cable management; daily necessities sales; technical services, technical development, technical consultation, technical exchange, technical transfer, technical promotion; Internet sales; domestic trade agents; trade brokers; sales agents; import and export agents ;Domestic freight forwarding agency;International freight forwarding agency; Technology import and export, licensing items: offshore trade operation

CS350 frequency converter is ABB's general mechanical transmission for the machine manufacturing industry. In the continuous production of machinery, the time spent in each unit is critical. From the steps of installation, parameter setting and debugging, this type of transmission is the fastest. The biggest advantage of ACS800 series drive products is that the same control technology is used uniformly in the full power range, such as startup wizard, custom programming, DTC control, common spare parts, common interface technology, and for selection, commissioning and maintenance. general software tools.

Advanced Technology – DTC: The core technology of ACS800 is Direct Torque Control (DTC). It is the most advanced control method of AC asynchronous motor at present. The stable and outstanding performance of DTC makes ACS800 transmission products suitable for various industrial fields.

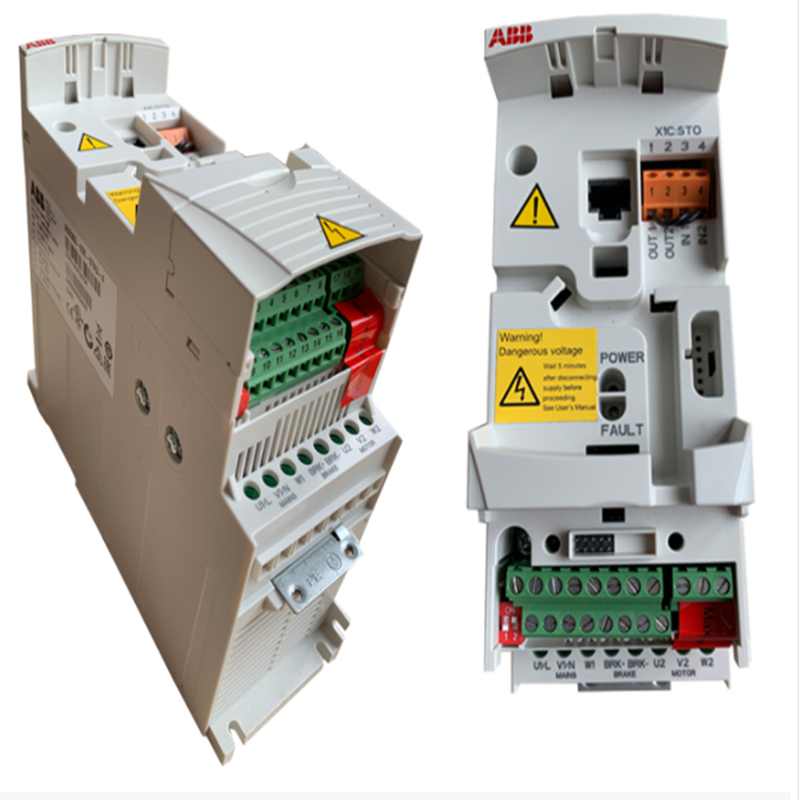

The figure above shows the appearance and wiring part of ABB inverter ACS510. It can be seen that the left part is analog input, digital input and relay input, power supply indication, communication interface, etc. It is mainly the input and output of the multi-function terminal of the control circuit. The right part is the main circuit part of the inverter, including U1, V1, W1 incoming power terminals, BRK+, BRK- are the braking resistor terminals, UDC+, UDC- are the chopper and braking unit terminals (the DC bus voltage is also Can be measured through this terminal), U2, V2, W2 are the wiring output to the motor terminal. It should be emphasized here that the input of the main power terminal of the traditional brand inverter is also marked as R, S, T and L1, L2, L3, and most of the output parts are U, V, W. Therefore, when connecting the ABB inverter, the input and output parts must not be reversed. Once reversed, it will directly cause the IGBT module of the inverter to be fried.

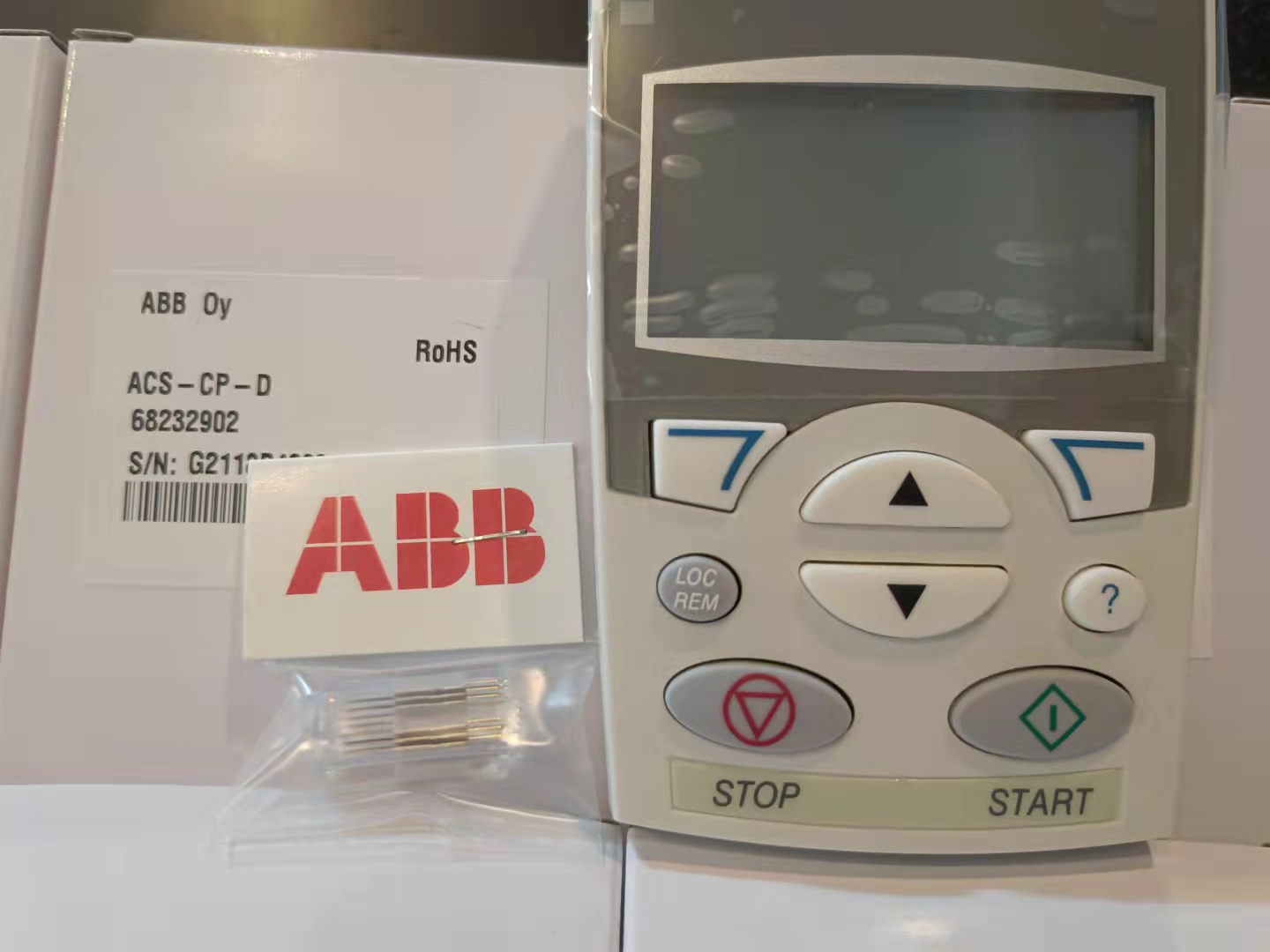

ABB inverter has two kinds of panels, one is Chinese panel as shown in the figure above, and the other is English panel, and its display part has only one line. Therefore, when purchasing the inverter, be sure to pay attention to the Chinese panel. According to the display part, you can enter the first-level menu through the menu key (soft key 2) to set the function parameters. LOC/REM on the keyboard is the remote and local switch key. If you need to control the panel, you need to do the following steps:

Step 1: Press the LOC/REM key when in local control. When LOC (local) is displayed on the display, it means that the inverter is in local control, that is, the control command comes from the keyboard. When REM (remote) is displayed on the display, it means that the inverter is in remote control, that is, the control command comes from the multi-function terminal or the way of communication. Step 2: When the inverter is under local control, press the START key, and the inverter is in the running state. Step 3: When the inverter is in the running state, by pressing (up key/down key) to increase or decrease the running frequency of the inverter, the speed adjustment of the inverter can be realized. Press STOP to stop the inverter. Step 4: In actual use, it is also necessary to set the parameters of the motor nameplate including frequency, current, voltage, speed and other parameters into the inverter to realize the functional protection of the motor by the inverter. Of course, if the power of the inverter matches the power of the motor, no additional settings are required.

Startup Wizard: ABB AC Drives is constantly improving the user interface. The application of the startup wizard makes the debugging of the ACS800 very easy.

Custom programming: Compared with traditional parameter programming, the custom programming of ACS800 has better adaptability. As the standard configuration of the whole series, it is like the transmission product has a built-in small PLC, and does not need to add any additional software and hardware. Highly integrated and compact structure design: As a standard configuration, all ACS800 series have built-in reactors. In addition, three optional modules can be installed in ACS800 at the same time: I/O expansion module, field bus adapter module, pulse programmer interface module or PC interface module.

There are no additional space and cable requirements for these modules. The new generation of all-round wall-mounted drives can simplify your production process and motor control, making it easy to save energy. At the same time, with simple and straightforward setup or commissioning, you can control various applications in different industries. Most basic functions are built-in as standard, simplifying drive selection without requiring additional hardware.

As a member of ABB's all-round drive product family, it is not only designed to provide a technically comprehensive drive, but also to provide an all-round solution, which is suitable for a variety of users, processes, business and environment. The ACS580 is ready to control pumps, fans, conveyors, mixers and many other variable and constant torque applications. ABB general machinery drives are designed to meet the needs of a wide range of machinery applications. The drive is ideal for applications in the video beverage, material handling, prevention, printing, rubber and plastics and woodworking machinery industries.

Excellent motor control performance for asynchronous and permanent magnet synchronous motors, 0.25 to 22 kW, 200 to 480 V Built-in optional EMC filter and Safe Torque Off (STO) No derating required at 50 °C in heavy duty version Independent air duct design reduces cooling airflow over electronic components The product is compact and small and supports side-by-side installation, making installation and debugging easy and fast Part of ABB's Compatible Drives Platform

Global availability, ABB provides global warranty, technical support and service. Perfect match for fans and pumps: Enhanced PFC application: up to 7 (1+6) pumps can be controlled; more pumps can be switched. S PFC: Circulation soft start function; each pump can be adjusted in turn. Multi-point U/F curve: 5-point U/F curve can be freely defined; it can be used flexibly and widely. Override mode: Fire mode applied to tunnel fans; used in emergency situations. PID regulator: Two independent built-in PID controllers: PID1 and PID2, two sets of parameters can be set for PID1; an independent external valve can be controlled through PID2.

Intuitive features: noise-optimized, increased switching frequency when drive temperature decreases, controllable cooling fan, activated only when needed; switching frequency can be randomly distributed to reduce noise, greatly improve motor noise, reduce drive noise and improve effect.

Flux optimization: Automatically reduces motor flux when the load is reduced; greatly reduces energy consumption and noise. Connectivity: Simple installation, can be installed side by side, easy to connect cables, easy to connect to the fieldbus system through a variety of I/O connections and plug-in options; reduce installation time, save installation space, and reliable cable connection.

EMC: RFI filters for first and second environments are standard; no additional external filters are required.

Reactor: Varying Reactor: Match inductance according to different loads, so suppress and reduce harmonics; reduce total harmonics

Others: Advanced control panel: 2 function keys, the function changes with different states, built-in help key, modified parameter list; easy configuration and debugging, quick start, quick access to parameters.

Fieldbus: Built-in RS485 interface, using Modbus protocol, plug-in fieldbus module as an option; reducing cost.

| Rated Frequency | 50 - 60 hz |

|---|---|

| Type | ACS800 |

| Catalogue Download | M3AA Motors |

| Brand | ABB |